Recycling Solutions

In recent years, there has been an increase in demand for companies to address social issues such as climate change and carbon neutrality. Plastics are now an indispensable part of our lives, and how to dispose of these resources is one of the issues that companies are required to address.

artience group has been working to promote the recycling of plastic resources and material recycling through the development of products and technologies and collaboration with other companies. We will contribute to the realization of a sustainable society by utilizing the technologies and knowledge we have cultivated over many years, such as the establishment of a recycling system for film packaging such as refillable pouches for food packaging and toiletry products, and the development of pressure sensitive adhesives for labels that are easy to peel off from PET bottles.

Package

Plastic packaging accounts for a large portion of waste plastic emissions. Among them, many film packages have a multi-layer structure, so various problems need to be solved in order to expand recycling in the future.

For example, mono-materials are attracting attention as one of the ways to improve the recyclability of packaging, but in order to do so, it is necessary to realize the necessary functions such as shelf-life and strength that were demonstrated in multi-layer configurations even with a single material.

Therefore, artience group is working to develop products that solve various problems caused by mono-materialization and to promote the use of mono-materials in packaging.

In addition, with the aim of further improving recyclability, we have established a technology to remove "printing inks" and "adhesives" from packaging in the recycling process, and have succeeded in extracting higher-quality recycled plastics.

Furthermore, based on these technologies, we will not only develop materials, but also build a recycling system together with many partners such as brand owners, converters, machine manufacturers, and recyclers.

Mono-Material Solutions

We are developing products that achieve functions such as shelf life and strength even with a single material, and we are working to promote the use of mono-materials for packaging.

Packaging Recycling Solutions

We are working to recycle used plastics by establishing technology for peeling off ink and adhesives and building a recycling system.

Label

Labels that cannot be removed by the alkaline cleaning process in the recycling process cannot be recycled. Therefore, there is a need for labels that do not leave impurities such as pressure sensitive adhesives on the packaging and that are easy to remove during the recycling process.

artience group 's TOYOCHEM has leveraged its years of polymer technology to develop a label pressure sensitive adhesives that enables plastic recycling. We will contribute to the promotion of the recycling of plastic containers and packaging such as PET bottles and food trays.

Other processed plastics

Conductive Sheets

Conductive sheets are made by coating a plastic substrate with conductive and antistatic inks, and are mainly used in trays and carrier tapes for conveying electronic components used in electrical appliances and automobiles to protect them from static electricity.

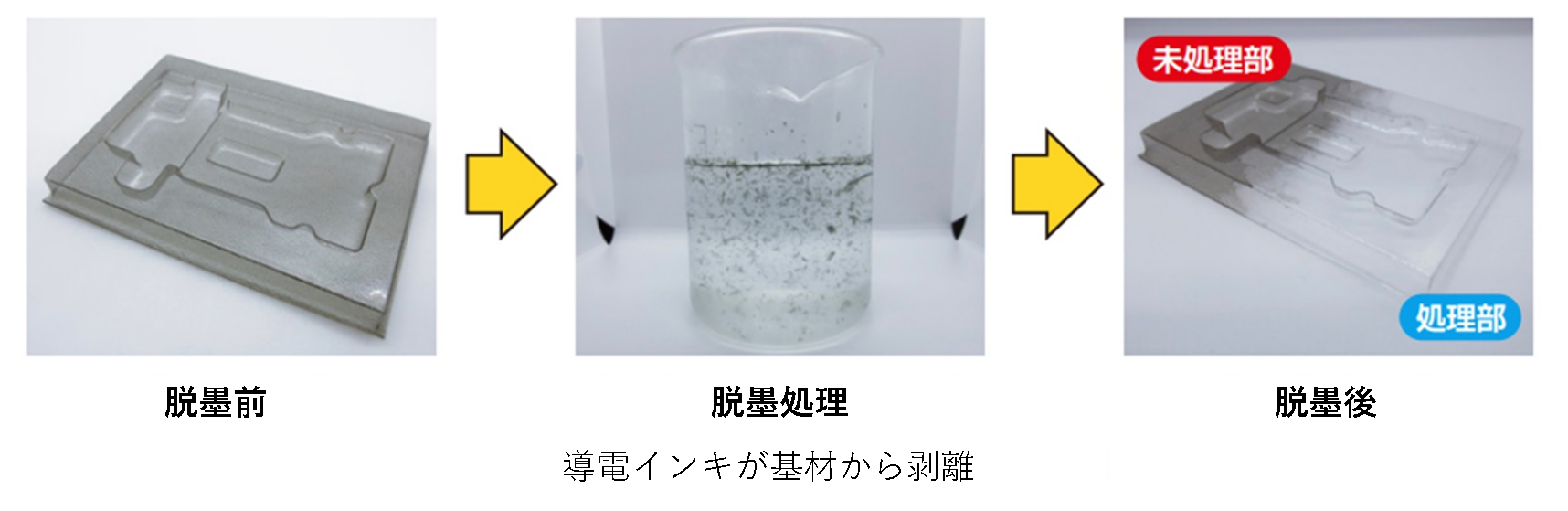

TOYO INK, in collaboration with Maruai Inc., has developed a "recyclable conductive sheet" that can be reused as a new raw material by deinking conductive ink from a plastic substrate. The development of a conductive sheet that can deink printed conductive ink is the industry's first*. This makes it possible to reuse used plastic substrates that were previously disposed of as plastic waste as plastic raw materials.

* Japan in the domestic conductive sheet industry. As of January 2024, according to Maruai's research.

Vending machine product sample sheets

TOYO INK is collaborating with Kyodo Production Co., Ltd. to deinking the product sample sheets used in vending machines. The main body of beverage containers is being recycled, but it is difficult to recycle sample products from vending machines, and the current situation is that there is no choice but to dispose of them. In the past, efforts have been made to reduce plastic by switching product samples from three-dimensional dummy cans to flat sheets made of PET, but by using a TOYO INK deinking coating when printing product sample sheets, it is possible to remove UV-curable inks and extract almost transparent recycled plastic at the time of recycling.

Inquiries

artience Co., Ltd.