Packaging Recycling Solutions

artience group, which has the largest share of packaging inks and adhesives in Japan, is working to recycle used plastics by establishing technology for removing ink and adhesives and building a recycling system.

- Challenges of Packaging Recycling

- Inks and adhesives Removal Technology

- Establishment of a recycling scheme through collaboration

- Examples of Initiatives with Customers

Challenges of Packaging Recycling

Most plastic packages are printed with ink to enhance the design, as well as the product name, ingredients, and precautions. In addition, film packaging, such as food packaging and refillable pouches for toiletry products such as detergents, is often composed of multi-layer structures made of polyolefins, polyesters, and other films bonded together with adhesives to ensure the performance requirements of different applications.

The packaging integral printing inks and adhesives are designed not to be easily removed from plastic, making them difficult to remove during the recycling process, and the inability to extract high-quality recycled plastics has limited the use of recycled plastics.

In order to solve this problem, artience group has established technology to remove deinking * and adhesives of printing inks, which are used in plastic packaging, mainly TOYO INK, and is working to improve the quality of recycled plastics.

* Deinking: Peeling and removing printing inks from a substrate

Inks and adhesives Removal Technology

Film Packages: Coating agent for deinking, laminating adhesives for peeling

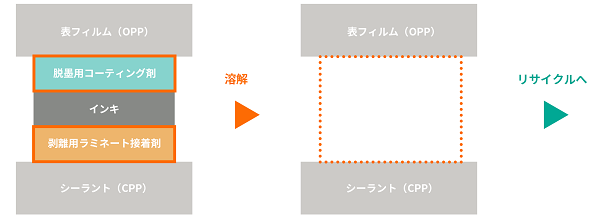

TOYO INK has developed a deinking coating and a peeling laminating adhesives to enable material recycling of multi-layer plastic packaging.

By replacing the conventional laminating adhesives with a "laminating adhesives for peeling" and applying a "deinking coating" between the plastic film and the printing inks, it is possible to remove ink and adhesives from the plastic film and extract recycled plastic that is almost transparent.

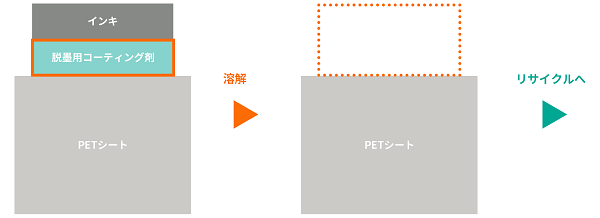

Hard plastics: Deinking coatings for UV-curable inks

UV-curable inks, which is used to print hard plastics such as clear packages, has been difficult to deink because the coating film is hardened. By applying a "deinking coating agent for UV-curable inks" between the hard plastic and the ink, it is possible to remove UV-curable inks by alkali treatment.

We have a lineup of two types, water-based (heat drying) and UV-curable type, and are compatible with various coating methods such as offset, flexograph, resin letterpress, and coater.

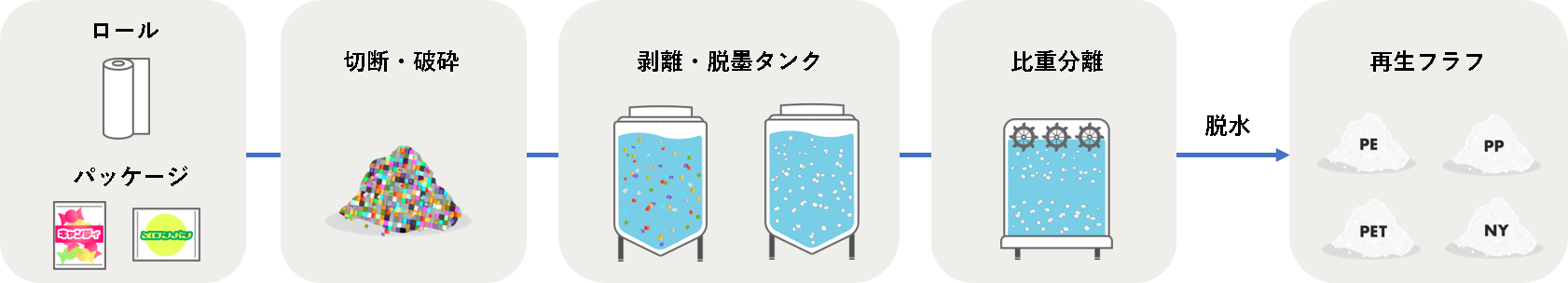

Peeling and deinking process

In plastic recycling, after crushing used plastics, alkaline treatment is used to peel off and deinking printing inks and adhesives, making it possible to recover high-quality recycled plastics that are almost transparent.

artience group has built a demonstration pilot plant of the recycling system in its own factory, and is not only developing materials for peeling and deinking, but also verifying the establishment of more efficient processes.

In addition, on November 27, 2023, we signed a joint development agreement with machine manufacturers Aikawa Iron Works Co., Ltd. and Hagiwara Kogyo Co., Ltd. for the purpose of implementing this recycling system in society. By combining Aikawa Iron Works' know-how cultivated in the paper industry such as recycling finers (beating equipment), waste paper deinking, and foreign matter separation, and Hagiwara Kogyo's recycling equipment and engineering technology and know-how such as advanced filtration, tempering and reforming technology in pellet recycling, and our peeling and deinking technology, we will develop, improve, and optimize equipment and processes. Through these initiatives, we aim to provide the market with a recycling system for cleaning, deinking, separating and recycling different materials as a single package.

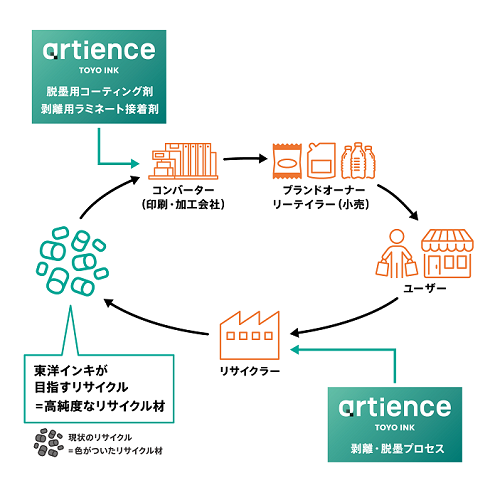

Establishment of a recycling scheme through collaboration

Plastic recycling cannot be achieved only by the development of peeling and deinking technologies. It is necessary to build a complete recycling system, from the production of packaging and moldings, to the collection of offcuts and used plastics from processing, to the use of recycled plastics.

artience group 's TOYO INK is working with many partners, including converters, brand owners, retailers, users, and recyclers, to build a recycling system.

Examples of Initiatives with Customers

J-Film Co., Ltd.: Clear packaging for packaging

Nearly 30% of the plastic used in clear packaging for packaging, which is said to be thousands of tons per year, is generated in printing plants and molding processing plants, but since most of it is covered with ink, the horizontal recycling rate of clear sheets, which are the raw material, is less than 10%.

We are conducting demonstration experiments with the aim of commercializing a recycling system for scrap materials generated in printing plants and molding processing plants, and establishing a system that can recycle the entire amount of scrap materials, including collection from the market.

Inquiries

TOYO INK CO., LTD. Sustainable Packaging Department

TEL:+81-3-3272-0919