Base material joining tape (Splice tape)

Although it has only one role, the selection of this tape has a major impact on improving production efficiency and process improvement.

- What is base material binding tape?

- Issues at the production site

- Points to solve

- Product Lineup

- Notes in Use

- Points to Note When Storing

- Featured Products

What is base material binding tape?

・Offset printing

・Gravure printing

・Flexo printing

・Adhesive processing

・Coating processing

・Lamination processing

Issues at the production site

The tape won't stick due to the cold winter weather.

In general, the adhesive strength of tape decreases in low-temperature environments, making it more likely to cause problems such as peeling.

This can be a serious problem, especially in the winter. In some cases, it may be necessary to keep the tape warm, and you may be forced to take measures such as storing the tape in a heated area.

I have to slow down when making transitions.

Depending on the type of base material and the tape used, connecting the base materials at high speed may cause problems such as tape peeling and damage to the base material.

Therefore, it is necessary to reduce the machining speed at the time of joining, which causes a decrease in work efficiency.

The tape is damaged by the heat during processing.

When processing in high-temperature environments, such as vapor deposition, sputtering, and adhesive processing, the high heat may cause the tape to lift, peel, or seep out of pressure sensitive adhesives, which can reduce work efficiency.

Points to solve

Strengths of TOYOCHEM products

TOYOCHEM base material binding tapes "Double-Face ™ DF4000 Series" and "LIOELM ™ LE831P Series"

For many years, we have supported the realization of stable production at major printing companies and converters.

Strong adhesion even in low temperature environments of 0°C

The unique pressure sensitive adhesives design improves adhesion in low-temperature environments, and exhibits the same performance even at 0°C as at room temperature (23°C). Stable work is possible regardless of climate conditions, both in winter and other seasons.

Compatible with high speed machining of 200m/min or more

Because it has excellent initial adhesive strength, it does not peel off even at high speeds, allowing you to join base materials while maintaining processing speed. It has been used at speeds of over 200m/min for film gravure and over 400m/min for newspaper printing.

Can be used regardless of base material type or processing method

Widely compatible with major base materials such as various printing papers, OPP, PET, NY, etc. In addition, it can be used for any purpose, including gravure printing, flexographic printing, offset printing, newspaper printing, and various film coatings.

High heat resistant tape is also available

For customers who perform processes in high-temperature environments such as vapor deposition, sputtering, and adhesive processing, we also offer high heat-resistant tapes that use silicone pressure sensitive adhesives.

Product Lineup

| Low temperature adhesion | Suitable for high speed | Heat resistance | |

|---|---|---|---|

| Double-Face ™ DF4000 series |

◎ | ◎ | △ |

| LIOELM ™ LE831 series |

〇 | 〇 | ◎ |

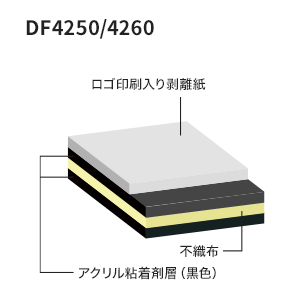

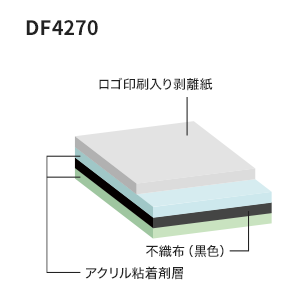

Double-Face ™ DF4000 Series(double-sided tapes)

double-sided tapes The Double-Face ™ DF4000 series provides strong adhesion even in low-temperature environments as low as 0°C, and can be used stably without peeling even when processing at high speeds.

It is colored red and black for excellent visibility to instantly identify the joint. We have a lineup of product numbers of different thicknesses.

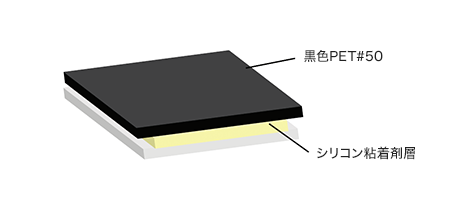

LIOELM ™ LE831 Series (Single-Sided Tape)

For applications in high-temperature environments such as vapor deposition, sputtering, and adhesive processing, the lineup of single-sided tapes made of high-heat-resistant silicone pressure sensitive adhesives" LIOELM ™ LE831P-BK" is available. Adhesion to the silicone peeling surface is also possible.

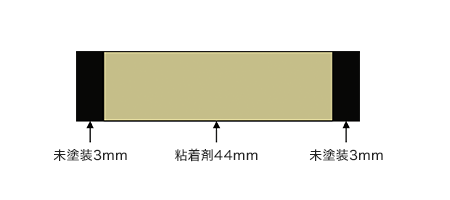

Both ends are not coated with pressure sensitive adhesives (part-coat), so there is no need to worry about pressure sensitive adhesives sticking out.

Performance table

| Item (unit) | Double-Face™ DF4110 | Double-Face™ DF4120 | Double-Face™ DF4250 | Double-Face™ DF4260 | Double-Face™ DF4270 | LIOELM ™ LE831-P50 BK |

|---|---|---|---|---|---|---|

| color | red | red | black | black | black | black |

| Adhesive tape thickness (μm) | 140 | 105 | 105 | 70 | 140 | 80 |

| Release liner thickness (μm) | 129 | 135 | 135 | 135 | 135 | 50 |

| Compatible base material | Newspaper, coated paper, liner paper, thin paper, OPP, PET, NY, cellophane, various transparent vapor deposited films, etc. * Please check compatibility before use |

|||||

| Adhesive stainless steel 0℃(N/25mm) |

17.6 | 14.7 | 14.7 | 10.3 | 17.6 | - |

| Adhesive stainless steel 23℃ (N/25mm) |

13.7 | 11.8 | 11.8 | 8.8 | 13.7 | 11.7 |

| Holding force 80℃ (mm) | 0.1 | 0.1 | 0.1 | 0.0 | 0.1 | 0.0

* 150℃1hr |

| ball tuck | 14 | 10 | 10 | 9 | 14 | 11 |

| Technical | DF4110 | DF4120 | DF4250 | DF4260 | DF4270 | LE831P-50BK |

Notes in Use

- Clean the adherend (Remove dust, any other foreign particles, water, and oil.)

- Make sure that the adherend is free of burrs and warpage.

- Apply the tape to the adherend at a temperature of around 20 degrees centigrade wherever possible.

- After applying the tape, press firmly.

- Be sure to conduct a test before using the tape to check that the tape is suited for the application.

- These tapes are for industrial use only. Do not use them for the following applications.

・Applications that involve or may involve the direct attachment of the tape to the skin.

・Applications that involve the direct attachment of the tape to food.

Notes on strage

- Store the product in a room away from sunlight. Keep it away from high temperatures and humidity. (The desirable temperature is 5 to 40 degrees centigrade, and the desirable humidity is 60% or lower.)

- Avoid placing the product directly on the ground or floor. Place it on a table that allows air to pass through.

- When storing tapes in a stack, be sure to insert a removable material, such as inserting paper, between the tapes and stack them vertically.

Featured Products

Inquiries

TOYOCHEM CO., LTD. Information and Communication Materials Sales Division

TEL:+81-3-3272-0930