Heat-resistant coating

When changing the structure of a package, the melting point of the film may decrease, which can lead to reduced production efficiency during bag making. The Z327 Heat-Resistant Coating helps address this issue by expanding the heat-sealable temperature range by approximately 20°C, contributing to improved packaging productivity.

Features

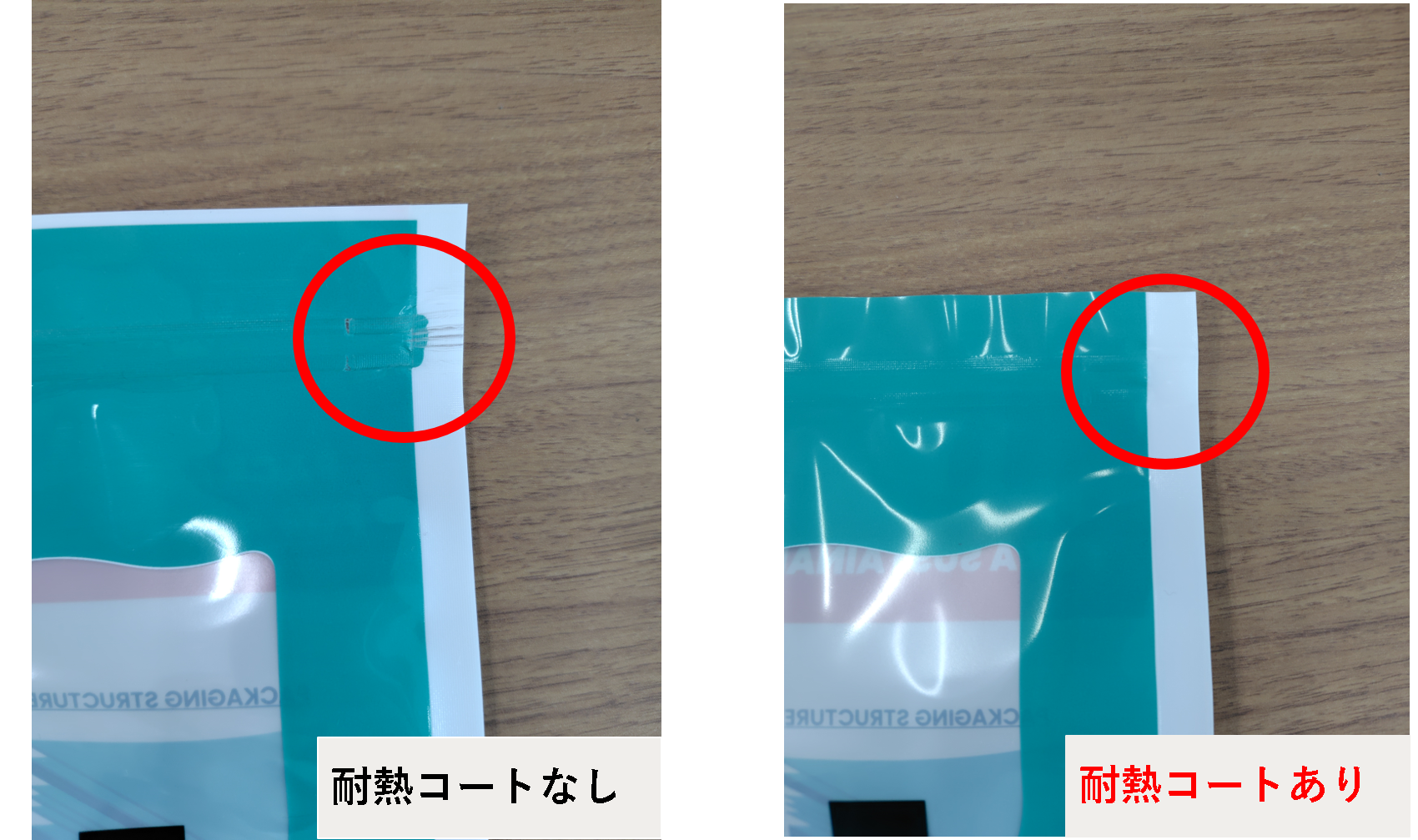

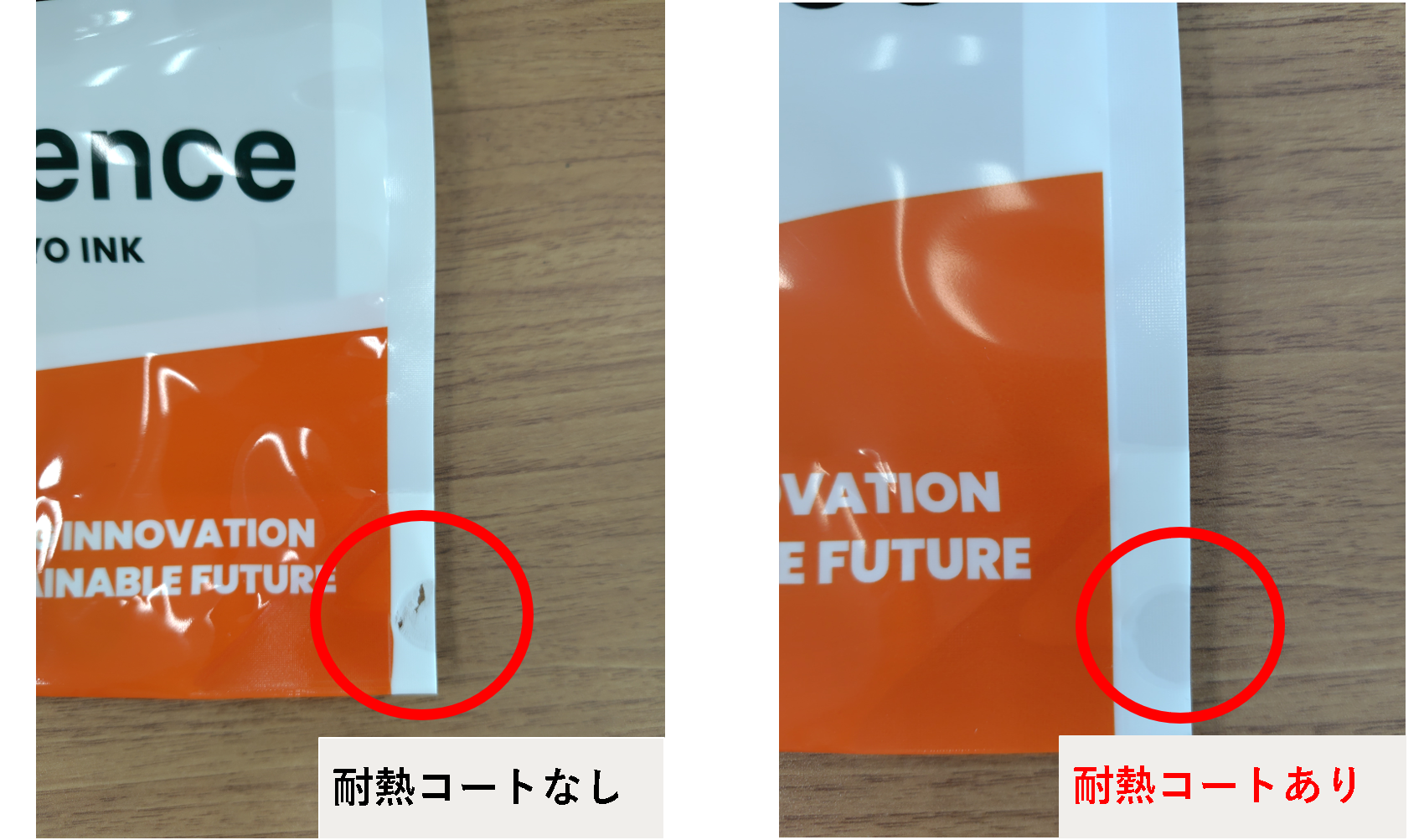

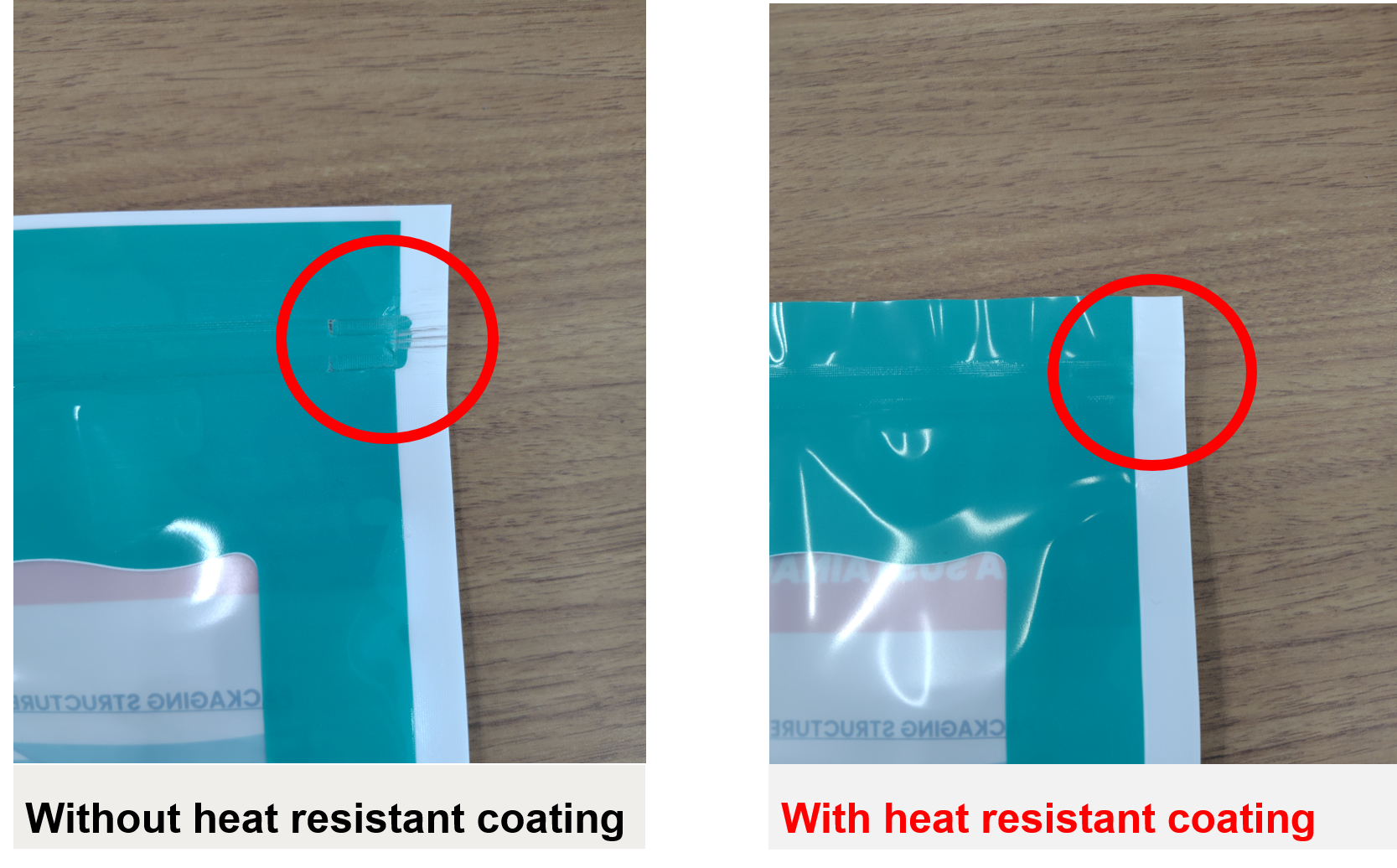

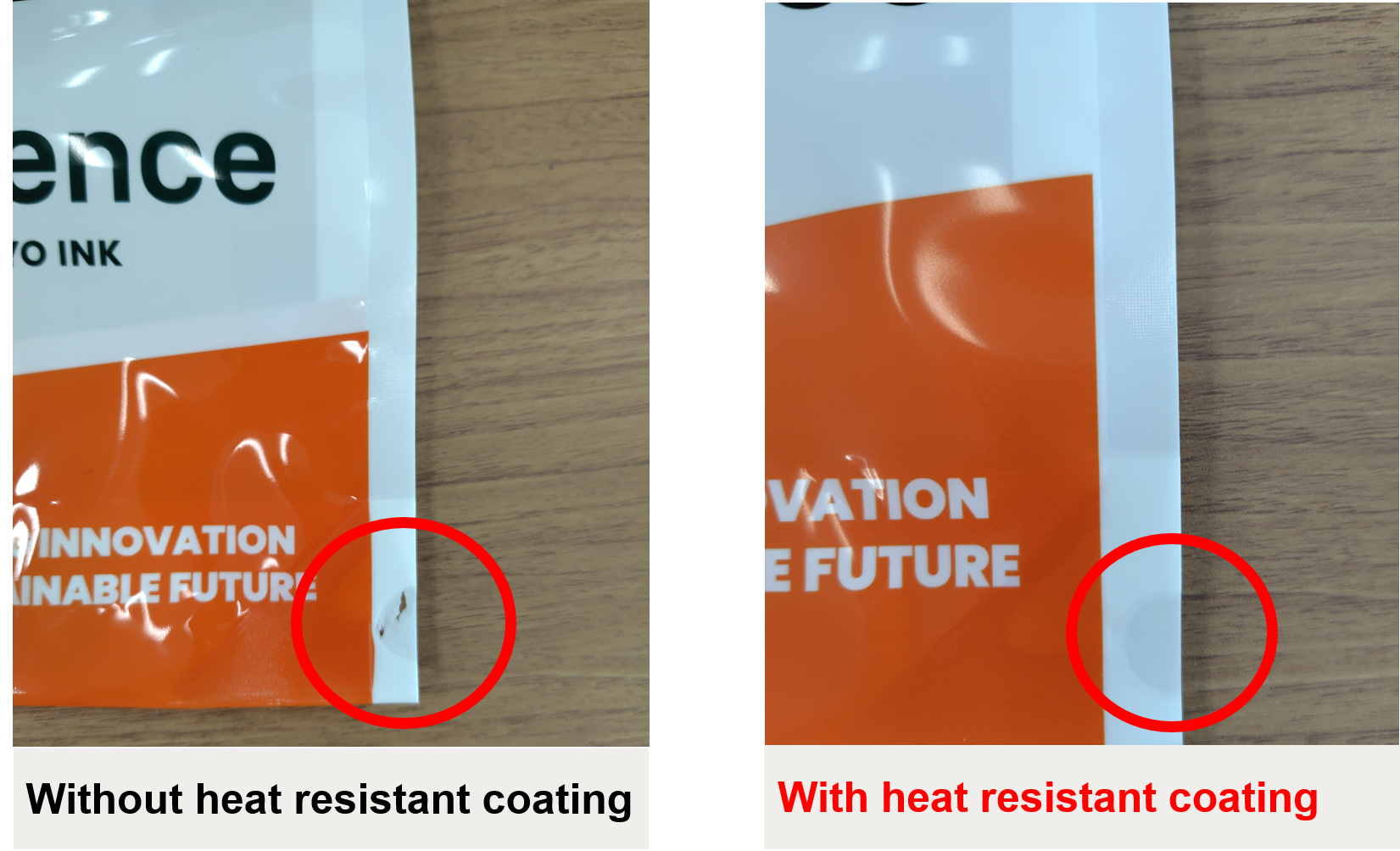

When modifying packaging structures—such as in the shift toward mono-materialization—the melting point of the film may decrease. This can lead to issues during bag making, such as heat shrinkage, curling, film breakage, and adhesion to the heat-sealing bar.

Typically, these issues are addressed by lowering the heat seal temperature, but doing so also slows down the bag-making speed, resulting in a decline in production efficiency.

By printing the Z327 Heat-Resistant Coating on the outermost film layer, the heat-sealable temperature range can be expanded by approximately 20°C, contributing to improved productivity in the packaging process.

Improved accuracy in printed pattern alignment

Reduced film breakage in laminated two-layer areas

Enhanced bonding stability between base film surfaces

Improved accuracy in printed pattern alignment

Reduced film breakage in laminated two-layer areas

Enhanced bonding stability between base film surfaces

Physical properties

Heat Shrinkage Evaluation (Simplified Test)

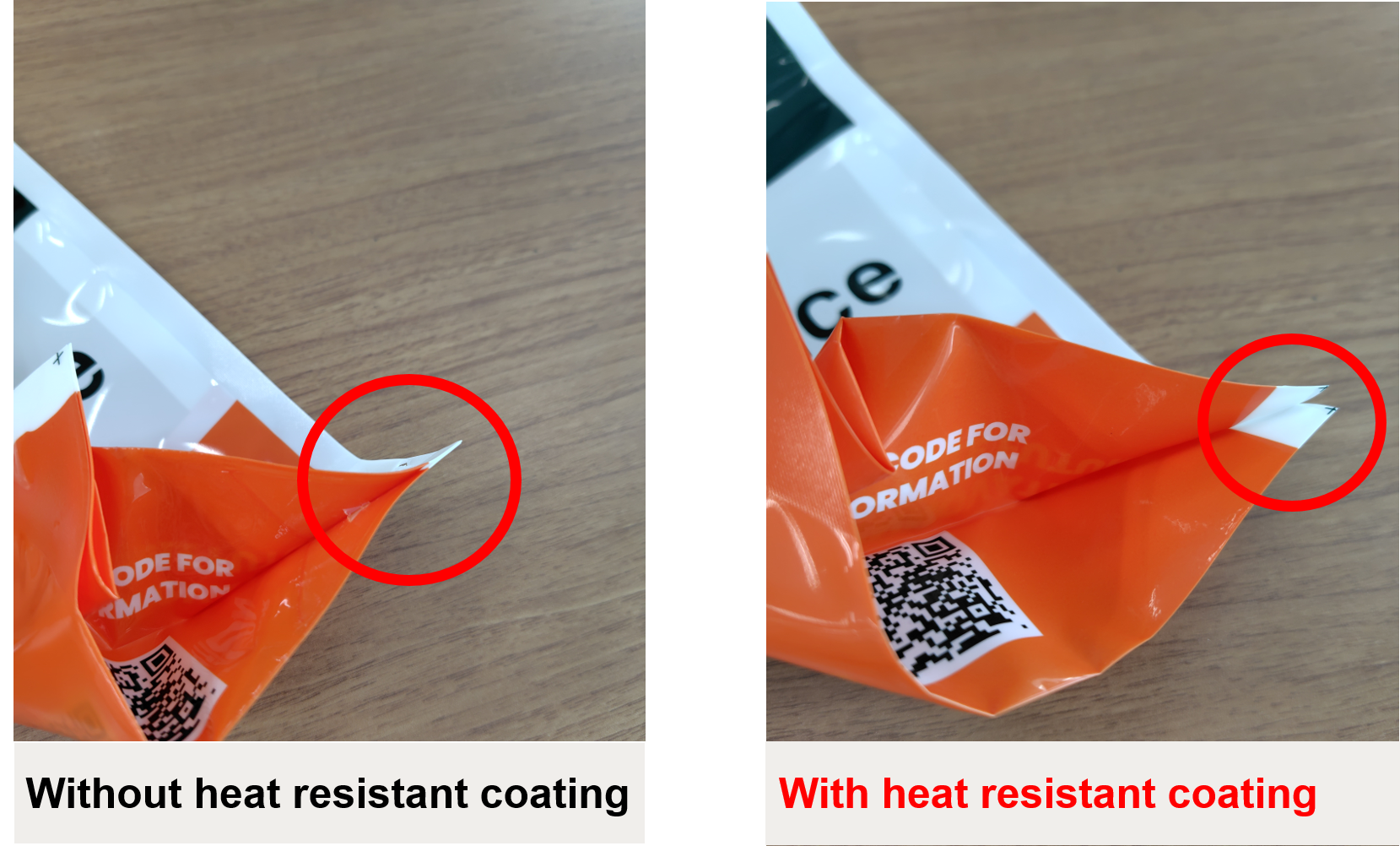

Under a sealing time of 1 second, without using the coating agent, the film stretches at a sealing temperature of 130°C and breaks at 140°C.

In contrast, when using the Z327 Heat-Resistant Coating, heat sealing can be performed without any issues even at 150°C.

| Heat seal temperature | Uncoated |

With Z327 heat resistant coating |

|---|---|---|

|

120℃ |

〇 | 〇 |

|

130℃ |

△(film elongation) |

〇 |

|

140℃ |

× (film breaking) | 〇 |

| 150℃ | - | 〇 |

【Evaluation Conditions】

Structure: Z327 Heat-Resistant Coating / MDOPE (25 µm) / Ink / Adhesive / LLDPE (50 µm)

Sealing Temperature: 120–150°C,

Sealing Pressure: 2 kgf/cm²

Sealing Time: 1 s

Heat Shrinkage Evaluation (Actual Equipment Test)

Under conditions of 125 ms × 4 sealing time, the film breaks at 240°C when the coating agent is not used.

In contrast, when using the Z327 Heat-Resistant Coating, heat sealing can be performed without issues even at 260°C.

| Heat seal temperature | Uncoated |

With Z327 heat resistant coating |

|---|---|---|

|

230℃ |

〇 | 〇 |

|

240℃ |

× (film breaking) | 〇 |

|

250℃ |

- | 〇 |

| 260℃ | - | 〇 |

| 270℃ | - | × (film breaking) |

【Evaluation Conditions】

Structure: Z327 Heat-Resistant Coating / MDOPE (25 μm) / Ink / Adhesive / LLDPE (100 μm)

Production Speed: 193 shots/min

Sealing Temperature: 240–270 °C,Sealing Time: 125 ms × 4

Seal Bar Protection: Teflon

* Evaluation conducted using a bag-making machine owned by Totani Giken Kogyo Co., Ltd.

Inquiries

TOYO INK CO., LTD. Marketing Headquarters

TEL:+81-3-3272-7693