A pressure sensitive adhesives made of natural materials that adheres tightly

Environmentally friendly and recommended for PE and PP that do not stick easily

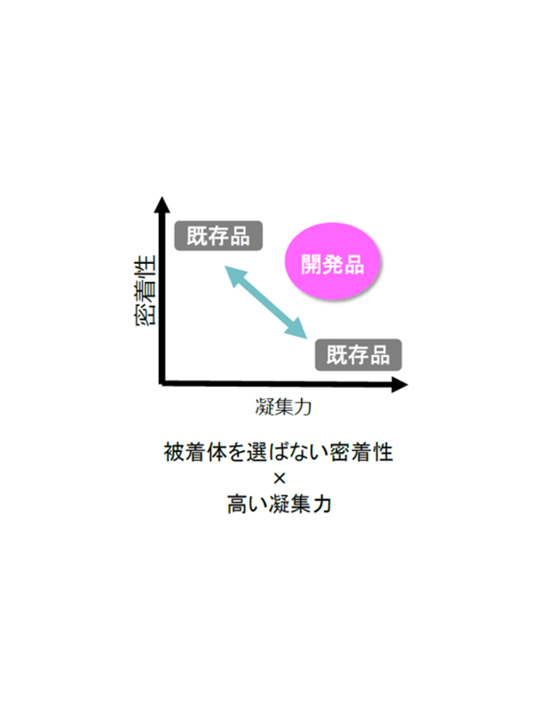

It is an environmentally friendly biomass pressure sensitive adhesives that does not have to choose the substrate (attachment partner) that is not found in conventional products.

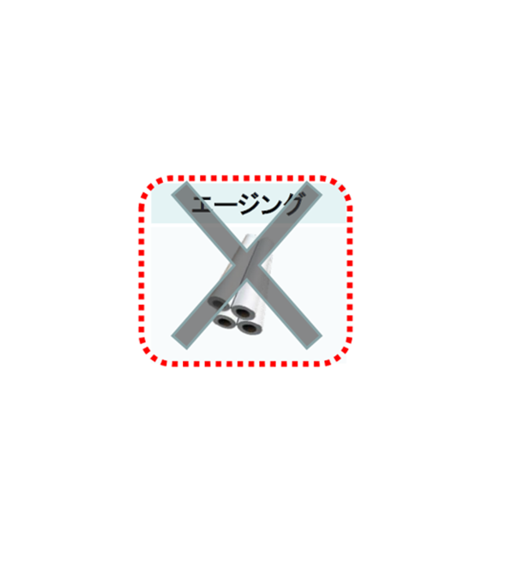

It is a one-component strong adhesive type that does not require aging.

Product features

Non-edible biomass raw materials are used as the main ingredient

Click here for an overview of biomass pressure sensitive adhesives and other biomass pressure sensitive adhesives products.

Biomass pressure sensitive adhesivesExhibits strong adhesive strength even on materials such as PE and PP

Contributes to time reduction and reduction of work errors

Comparison of physical properties

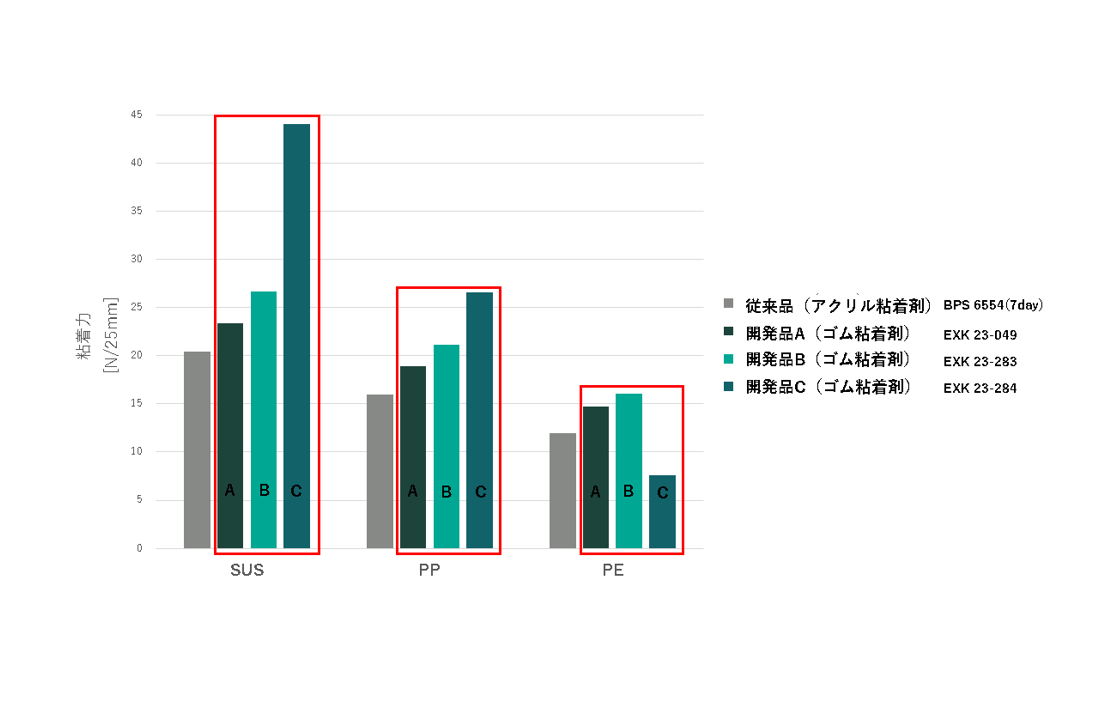

Adhesive force

The developed products A and B have the feature of exhibiting high adhesive strength regardless of the substrate, and the developed product C is an ultra-strong viscosity grade for SUS and PP that has never been seen before.

| product | Type | grade | Biomass degree: % (as dry weight) |

Adhesive strength N/25mm 24 hours after pasting | ||

|---|---|---|---|---|---|---|

| To SS | PP | PE | ||||

| Conventional product for comparison (BPS 6554) | Biomass (Acrylic) | Strong adhesive strength | 15 | 20.5 | 16.0 | 12.0 |

| Product A (EXK23-049) | Biomass (rubber) | Strong adhesive strength | 40 | 23.5 | 18.9 | 14.8 |

| Product B (EXK23-283) | Biomass (rubber) | Strong adhesive strength | 44 | 26.7 | 21.1 | 16.0 |

| Product C (EXK23-284) | Biomass (rubber) | Strong adhesive strength | 36 | 44.0 | 26.6 | 7.6 Z |

Z: zipping (a phenomenon that makes a jittery sound when peeling off)

Base material: 50μm PET

Application amount: 25g/m2 (DRY)

Holding force

Since the developed product does not require aging, it exhibits high cohesion immediately after coating.

| product | Type | grade | Biomass degree: % (as dry weight) |

Holding force [mm/70000 sec] 40℃ -1kg |

|

|---|---|---|---|---|---|

| To SS | |||||

| Conventional product for comparison (BPS 6554) | Biomass (Acrylic) | Strong adhesive strength | 15 | After coating drying: 600sec drop (After aging: NC) |

|

| Product A (EXK23-049) | Biomass (rubber) | Strong adhesive strength | 40 | 0.05mm | |

| Product B (EXK23-283) | Biomass (rubber) | Strong adhesive strength | 44 | N.C. | |

| Product C (EXK23-284) | Biomass (rubber) | Strong adhesive strength | 36 | N.C. | |

Aging condition: 23°C-50%RH 7 days

NC: No misalignment

Base material: 50μm PET

Application amount: 25g/m2 (DRY)

Other Environmentally Friendly Products

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-0940