Outgas suppression dry laminating adhesives

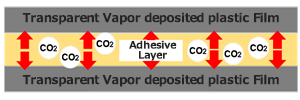

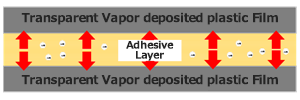

It is suitable for W barrier configurations and bonding between thick film substrates, and while suppressing the generation of CO2 generated during crosslinking, it improves appearance defects and stabilizes adhesive strength and heat resistance.

Features

- Low gas foaming/no foaming

- It is possible to laminate transparent vapor-deposited films together.

- High heat resistance

Application example

Laminate film

window glass insulation film

Product Data

| Product name | Main agent | hardening agent | Main agent | hardening agent |

|---|---|---|---|---|

| LIS-825 | CR-901 | LIS-7390 | LCR-1901 | |

| Resin composition | polyester | Aliphatic NCO (IPDI+HDI) | polyurethane | epoxy |

| Mixing ratio (NV) | 100(50%) | 7~10(70%) | 100(60%) | 7(95%) |

| Viscosity (mPa・s) | 600 | 100 | 1800 | 100 |

| Characteristics | Low gas foaming/heat resistance | Non-foaming | ||

| Aging conditions | 60℃/3 days or more | 40℃/2 days | ||

| PCT test initial strength | 16N/15mm width | 6N/15mm width | ||

| PCT exam 168 hours | 6N/15mm width | 2N/15mm width | ||

- Layer configuration: CPP//CPP, retort CPP used

- Aging: 40℃ 4 days

- Application amount: 5g/㎡Dry

* The above figures are measurements and not guarantees.

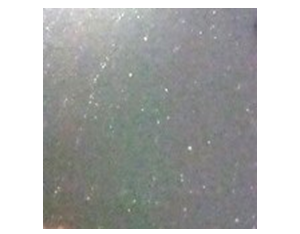

Laminate appearance comparison

When bonding barrier films to each other, appearance defects occur when using normal isocyanate cross-linked adhesives. LIS-825's low gas foaming performance provides high transparency and good appearance.

It will be done.

Conventional product

LIS-825/CR-901

Inquiries

Toyo-Morton, Ltd.

TEL:+81-3-3272-3394