High weather resistant dry laminating adhesives LIS-7059

This is an ultra-low hydrolyzable adhesives. It has a proven track record in various high-durability applications such as solar panels and insulating paper lamination.

Features

- durability

- Flexible and high initial strength

- Base material versatility

- Hydrolysis resistance

Application example

- High adhesion even after stretching

- Strong adhesion to PET

- Good heat resistance and durability

Product Data

| Product name | Main agent | hardening agent |

|---|---|---|

| LIS-7059 | LCR-1032 | |

| Resin composition | polyester resin | Aliphatic NCO |

| Non-volatile content | 50% | 85% |

| viscosity | 700mPa・s | 150mPa・s |

| Mixing ratio | 100 | 4 |

| Aging conditions | 40℃ or more/2 days or more | |

durability

Hydrolysis resistance

It has superior hydrolysis resistance compared to polyester adhesives.

| Survival rate | molecular weight Standard value 100% |

85℃85%RH After 1000hrs (Mw) |

|---|---|---|

| LIS-7059 | 100% | 80% |

| General polyester (For retort packaging) |

100% | 25% |

* The above figures are measurements and not guarantees.

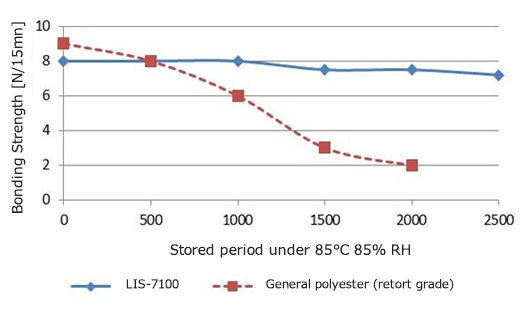

Durable adhesive strength

There is almost no decrease in adhesive strength after 2500 hours at 85°C and 85%.

Comparison of adhesive strength with general polyester adhesives

* Composition: PVDF/PET

* The above figures are measurements and not guarantees.

Inquiries

Toyo-Morton, Ltd.

TEL:+81-3-3272-3394