High heat resistant dry laminating adhesives TM-K76

adhesives has high heat resistance and resistance to various chemicals, and has a proven track record in a wide range of fields, mainly for electronic parts.

Features

- Adhesion with metal foil

- Heat resistance and suitability for post-processing (chemical resistance)

Application example

- High adhesion even after stretching

- Strong adhesion to PET

- Good heat resistance and durability

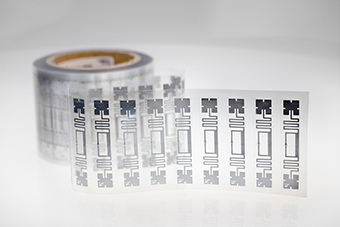

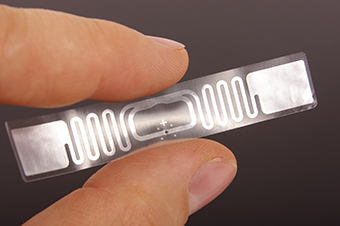

RFID film

RFID

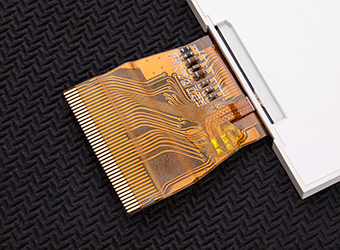

wiring film

Product Data

| Product name | Main agent | hardening agent |

|---|---|---|

| TM-K76 | CAT-RT85 | |

| Resin composition | polyester resin | Aliphatic NCO |

| Non-volatile content | 51% | 70% |

| viscosity | 2000mPa・s | 110mPa・s |

| Mixing ratio | 100 | 7 |

| Aging conditions | 60℃ or more/3 days or more | |

Measurement data example

adhesives durability

| Structure | CPP100μ // adhesives //CPP100μ |

|---|---|

| Room temperature adhesive strength | 23.0N/15mm (PI interface) |

| PCT 105℃×96 hours | 21.0N/15mm (film cohesive failure) |

| PCT 105℃×144 hours | 22.5N/15mm (film cohesive failure) |

Actual property data for polyimide/copper foil composition

| Structure | Polyimide 25μ // adhesives 8μ // Copper foil 12μ |

|---|---|

| Room temperature adhesive strength | 14.2N/15mm (PI interface) |

| 200℃×10 days later | 4.0N/15mm (cohesive failure) |

| Appearance after etching | PET/AD haze value increase: 3 or less |

Inquiries

Toyo-Morton, Ltd.

TEL:+81-3-3272-3394