Primer for concrete pouring/Highly durable floor finishing agent TM-7416

A civil engineering primer that can be applied to concrete pouring and infrastructure repair.

It can also be applied as a floor finishing agent by taking advantage of the gloss and durability of the dried paint film.

Features

- In addition to painting and adhering to normal concrete dry surfaces, it can also be applied as a primer to wet concrete surfaces for new concrete pouring.

- It has strong adhesive properties as a primer for pouring and pouring even on oil-contaminated concrete surfaces (oil-wet surfaces).

- It exhibits excellent adhesion even to different types of resin coatings.

- The coating surface has good gloss and has excellent chemical and water-based.

- A resin varnish for floor painting that is stain-resistant and has friction properties that prevent it from slipping even after water repellent.

- A paint varnish that can be easily applied to concrete using a wool roller or brush.

- Since it is a water-soluble resin, it can be cleaned with water.

Application example

- Adhesion of new and old concrete mortar joints

- Renovation floor repair adhesive primer (gas stations, factories, kitchens, warehouses, stores, etc.)

- Various renovations and repairs (tunnel walls, dams, roads, bridges, waterways, etc.)

Applicable base

Product Data

| Product name | Main agent | hardening agent |

|---|---|---|

| TM-7416 | CAT-1955 | |

| Appearance | Colorless to brown transparent | Colorless to pale yellow transparent |

| composition | acrylic resin | Epoxy resin |

| Non-volatile content | 40% | 70% |

| Viscosity (mPa・s) | Approximately 600 | Approximately 150 |

| Mixing ratio | 100 | 20 |

Adhesive performance

Adhesive strength

| dry surface | 22kg/cm2 (concrete breakage) |

|---|---|

| oily surface | 22kg/cm2 (concrete breakage) |

| wet surface | 20~24kg/cm2 (concrete breakage) |

Sample preparation conditions

Primer: TM-7416/CAT-1955 = 100 / 20

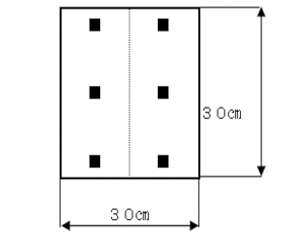

Base material: Concrete board (JIS A-5304) thickness 6㎠ moisture content 8%

Application method: 1 coat with brush

Application amount: Wet 150g/㎠

Evaluation method

Aging: Leave at room temperature for 7 days

Preparation of sample: Divide the concrete plate into two and measure at 6 points on each side (n = 3)

how to use

Diluent: water, IPA, ethanol

Combination example: TM-7416/diluent/CAT-1955=100/40/20

Application method: Woo roller, brush, etc.

Application amount: Wet 150-200g/㎥

Drying: room temperature drying

Curing: Dry at room temperature for 3 to 5 hours until tack-free, dry at room temperature for 1 week until completely cured

Pot life: 6-8 hours

Basic composition

- First, add the diluent (usually water) to the base material TM-7416, stir and mix, then add the curing agent and mix well.

- If the applied surface is extremely wet, remove the water adhering to the surface with a rag, etc., and use a mixture of water/alcohol (IPA, etc.) as the diluent mentioned above.

- If you need to speed up drying due to low winter temperatures, use a mixture of water/alcohol (IPA, etc.) as the diluent above.

Examples of diluents

When applying to wet surfaces: Water/IPA = 50/10

To improve dryness: water/IPA=55/5

Inquiries

Toyo-Morton, Ltd.

TEL:+81-3-3272-3394