Inkjet inks

TOYOCOLOR has cultivated ink technology in the packaging field for many years. Even in the field of package printing, where digitization is progressing, we provide solutions for a variety of applications, including flexible packaging, food labels, folding cartons, and cardboard.

We propose a new inkjet ink that is not only highly compatible with substrates, but also has image quality and printability approaching that of offset printing for digital packaging printing, which is becoming increasingly on-demand, variable, and personalized.

What is inkjet ink?

Inkjet ink is ink used for inkjet printing.

Inkjet printing, which started out as a general consumer application, is now used in a variety of applications, including sign graphics, textiles, building materials materials and wallpaper, publishing, commercial printing, cardboard, folding cartons, labels, and packaging, as well as precision equipment and the medical field. .

Inkjet inks are broadly divided into "solvent-based inks," "UV-curable inks," and "water-based inks," each of which has the following characteristics.

| solvent based ink | UV-curable inks | water-based ink | ||

|---|---|---|---|---|

| Environmental friendliness | ✕~△ | ○(non-VOC) | ◎ | |

| safety | △ | △ | ◎ | |

| Drying performance (productivity) | △~○ | ◎ | △ | |

| On-board stability | △ | ◎ | △ | |

| Base material versatility | paper | ✕ | ✕ | △~○ |

| film | exclusive | Various types○ | ✕ | |

| Abrasion/ water-based | ○/◎ | ○/◎ | △/△ | |

Features of inkjet printing

Inkjet printing does not require the creation of plates, so you can print what you need, when you need it, and in the amount you need. The main features are as follows.

print on demand

Information and patterns can be printed variably on each sheet. Not only can personal information and lot numbers be printed in monochrome on the packaging, but personalized designs can also be printed in full color.

small lot printing

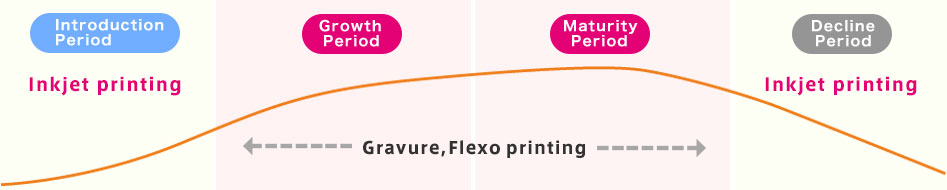

We can accept orders for printing in small lots. Therefore, it can be used even when the number of copies to be printed is small, such as during the introduction and decline stages of the product life cycle.

quick delivery printing

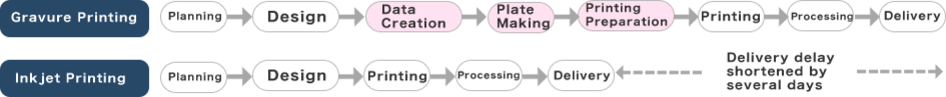

Since there is no need to create a plate, there is no plate-making process in the printing process, and printing delivery times can be shortened.

Features of our products

By combining the advanced dispersion technology that we have cultivated over many years with the technology of Group Companies, we are able to achieve high image quality and strengthen printing suitability for inkjet printing. We also comply with the laws and regulations of countries around the world and provide products that our customers can use with peace of mind.

① Higher image quality

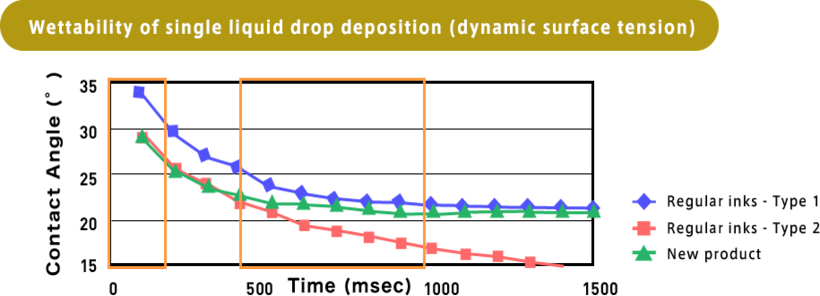

We contribute to high image quality of printed matter by controlling ink physical properties and wetting properties using substrate surface treatment technology, increasing density by controlling ink permeability, and achieving a wide color reproduction gamut by optimizing pigments design and spectral characteristics. Masu.

Wettability control

- Control of ink physical properties according to surface properties and permeability of printing substrate

- Substrate surface treatment technology using anchor materials

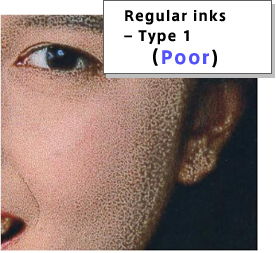

Printing samples of conventional ink types and developed products

Comparison of image quality

Conventional ink type ① (image quality △)

Conventional ink type ② (image quality ✕)

Developed product (image quality ○)

High concentration

- Improve print density by controlling ink permeability

By adding special surface conditioning agents and water-based solvents, filling of solid areas is greatly improved and printing density is increased.

Additionally, since the amount of ink required is reduced, drying and curing properties are also improved.

Effects of adding special surface conditioning agents and water-based solvents

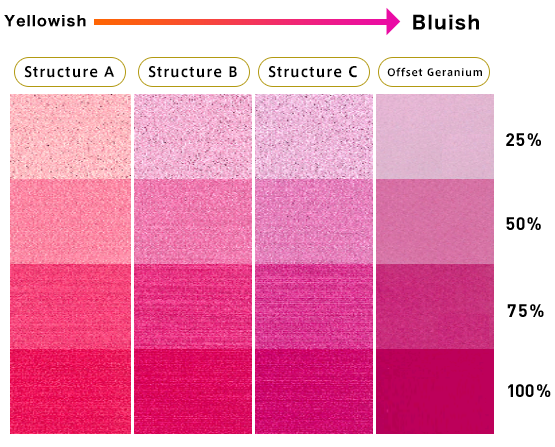

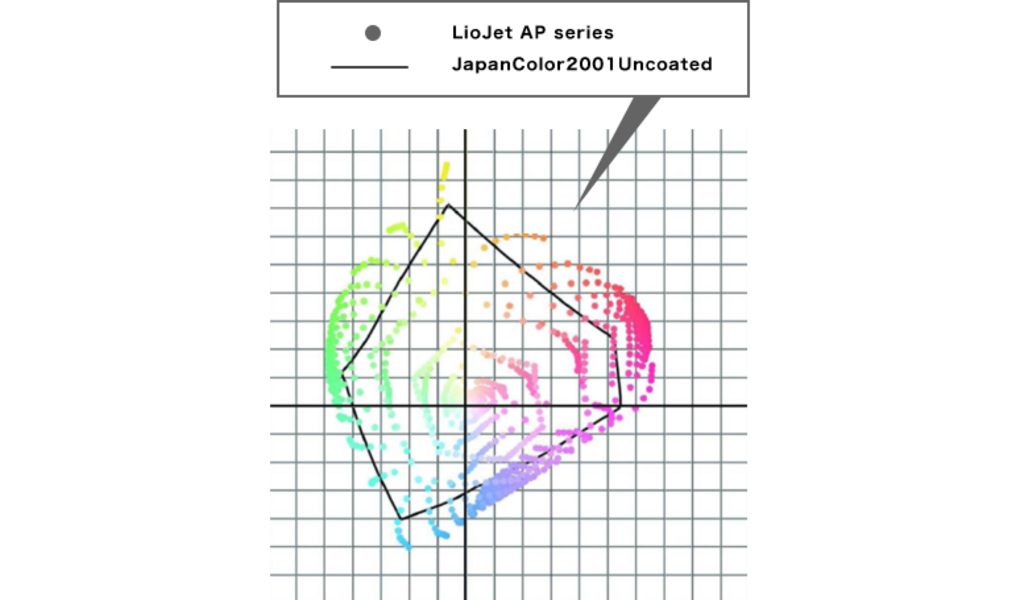

Color gamut, color reproducibility

- Achieving a wide color reproduction gamut by optimizing pigments design (selection) and spectral properties

We have developed offset color pigments that are suitable for inkjet printing and have achieved a wide color reproduction range.

Comparison of printed samples of conventional structure and developed product “Offset Beni”

Color reproduction range of the developed product “LioJet AP series”

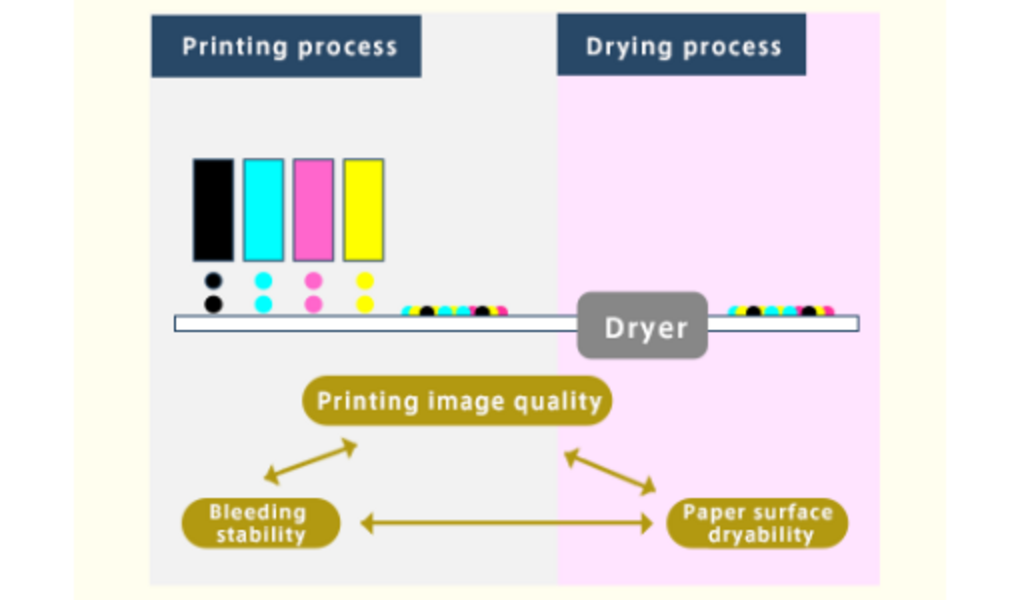

② Printability

High-speed printing was achieved through material design that takes into account the balance between inkjet ejection performance and drying performance, as well as appropriate wetting and spreading design on printing equipment. Additionally, we have improved printability by developing anchoring agents that enable the use of versatile base materials.

high speed printing

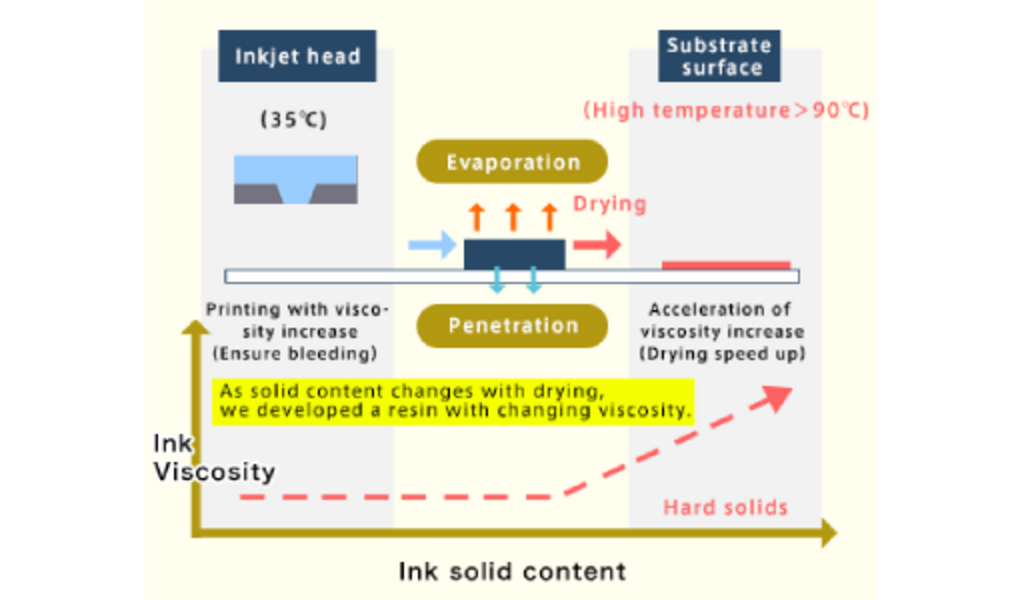

High-speed printing requires appropriate material design that takes into account the balance between inkjet ejection performance and drying properties, as well as appropriate wetting and spreading design on printing equipment. By developing a resin whose viscosity changes significantly as the solid content changes during drying, we have increased drying speed and achieved high-speed printing.

Balance between inkjet ejection performance and drying performance

Dry on paper without drying with an inkjet head

Generalization of base materials

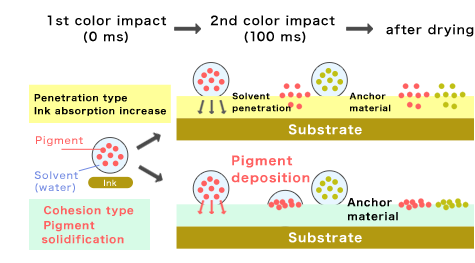

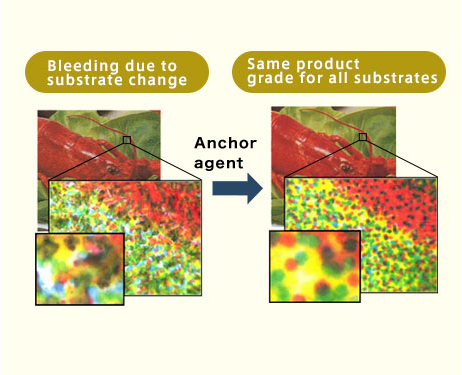

Normally, bleeding occurs when the printing substrate is changed. By using the anchoring agent developed by our company, we have made it possible to print with the same quality on all substrates.

Anchor agents are also effective in fixing large amounts of ink at high speed. The use of an aggregating anchor agent that has an advantage in fixing ink at high speed improves drying performance.

High-speed image formation technology using anchoring agents

Image of using anchor agent

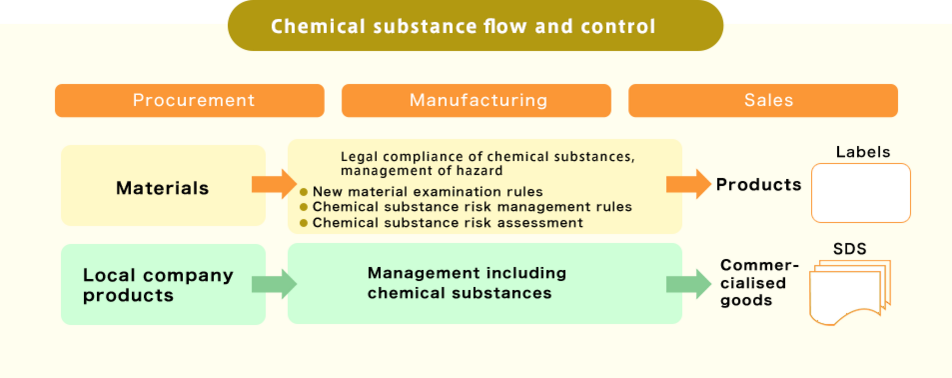

③ Comply with the laws and regulations of each country

artience group has established the "Global Chemical Substance Management Regulations" and is building and operating a system for unified standard management at overseas Group Companies. In addition, each overseas Group Companies is promoting the operation of the "Global Environmental System" (a unique system that manages laws and regulations and registration information, and creates SDS and labels compatible with each country). We centrally manage legal and regulatory information. This allows us to provide customers around the world with information on chemical substances in products and information on how to safely handle products in the local language through SDS and labels.

Additionally, countries overseas are enacting chemical substance registration systems similar to Europe's REACH and Japan's Chemical Substances Control Law. In response, we have built a system that allows us to promptly comply with the law by utilizing information networks among overseas Group Companies and by cooperating with overseas consultants. In particular, we are proactively providing information to the authorities in building an inventory of existing chemical substances in Thailand.

pigments dispersion is extremely important in inkjet inks to improve consistency in jetting performance, print quality, and final ink performance. Using advanced dispersion technology that we have cultivated over many years, we are able to precisely disperse pigments in microscopic particle sizes and maintain the separation of each particle, thereby improving the overall performance of the ink.

Additionally, we are able to combine the technologies cultivated by our Group Companies. Accelerate your business with one-stop innovation.

Inquiries

TOYOCOLOR CO., LTD. Coloring Materials Sales Department

TEL:+81-3-3272-0966