For thermal labels hot melts

Reduction of CO2 emissions and improvement of workability without mold release paper

- What is a thermal label?

- Advantages of hot melts thermal labels

- Performance of hot melts for thermal labels

- Other common labels

What is a thermal label?

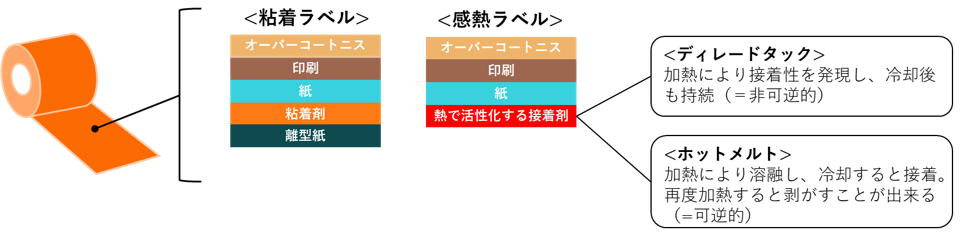

The most commonly used label for beverage and food containers is the "self-adhesive label". Adhesive labels are attached to containers by peeling off the release paper and crimping the adhesive surface. On the other hand, a "thermal label" is a label that does not have adhesive properties at room temperature, but activates the adhesives when heated, and can be attached to containers. A special labeler is used to heat the adhesives side and label the container.

Thermal labels are broadly classified into two types depending on the type of adhesives used: "delayed tuck type" and "hot melts type".

What is hot melts?

It is a adhesives that is solid at room temperature, but melts into liquid when heated and solidifies again when cooled.

See below for a detailed explanation.

What is Hot-melt? Environmentally friendly adhesives

What is the difference between adhesives, pressure sensitive adhesives, and hot melts

Advantages of hot melts thermal labels

| hot melts Thermal Label | adhesive labels | Delayed tuck thermal label | |

|---|---|---|---|

| CO2 emissions | ◎ | △ | ◎ |

| Biomass conversion |

〇 Compatible (biomass content 50% or more) |

〇 Yes |

× bad |

| Presence or absence of controlled substances (DHCP) | 〇 Not Contained |

〇 Not Contained |

× containing |

| Presence or absence of release paper | without ・Waste reduction ・Improvement of transportability of raw materials ・Lengthening of raw material is possible. (= Reduction of the frequency of roll switching) |

existence | none |

| Labeler | Thermal Labeler | Self-adhesive labeler | Thermal Labeler |

| Handling precautions | - | - |

Fear of × Powder Blowing Phenomenon |

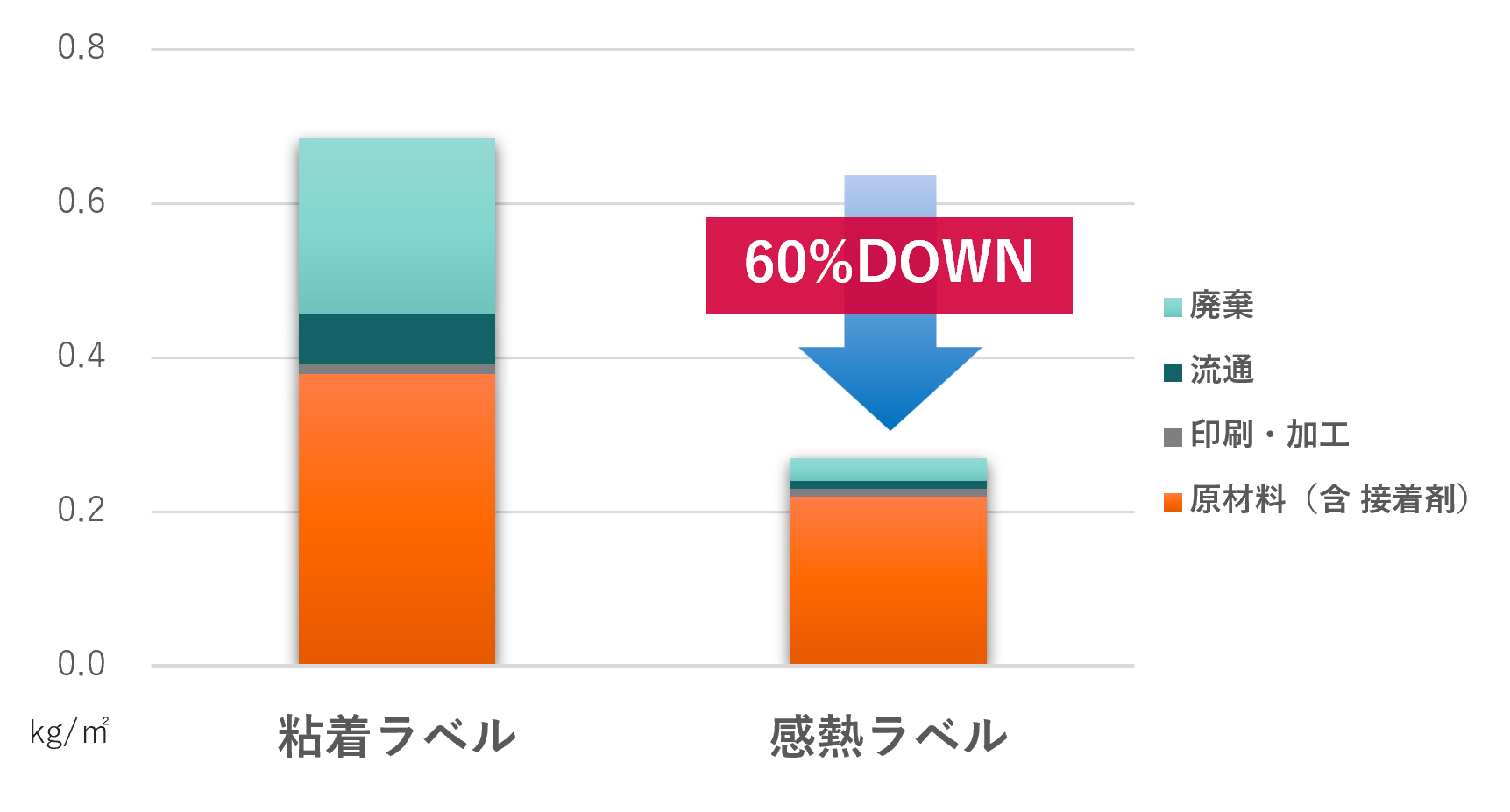

Comparison with self-adhesive labels

The absence of release paper has advantages in terms of environmental friendliness and workability

Example: When 100 million units are produced with a label area of 5 cm × 20 cm: 415 tons reduction * Self-adhesive label: 685 tons Thermal label: 270 tons

In addition, the configuration that does not require release paper leads to advantages such as reducing waste, improving the transportability of raw material rolls, and reducing the frequency of roll switching by lengthening them.

Example: When 100 million units are produced with a label area of 5 cm × 20 cm: 415 tons reduction * Self-adhesive label: 685 tons Thermal label: 270 tons

In addition, the configuration that does not require release paper leads to advantages such as reducing waste, improving the transportability of raw material rolls, and reducing the frequency of roll switching by lengthening them.

* Calculation conditions (1) Adhesive label (water-based) ... Basis weight: Paper label 85g/㎡, Release paper: Paper 50g/㎡ + PE 30μm, Coating amount: 20g/㎡ (DRY), Solid content: Acrylic 60% (with drying process), Process paper: Basis weight 300g/㎡ (used 10 times) (2) Thermal label... Thickness: Paper label 85g/m2, hot melts Usage: 12g/㎡

Comparison with delayed-tuck thermal labels

Although they share the common point that they are configured without release paper, hot melts-type thermal labels have the following advantages:

| Delayed Tack |

|

|---|---|

| Hot-melt |

|

Performance of hot melts for thermal labels

LABELMELT ™ BL-8506A (under development) Basic physical properties

| viscosity |

(150°C) 5,300mPa・S (160°C) 4,000mPa・S |

|---|---|

| Softening point | 72℃ |

| Hue | Pale yellow |

| biomass degree | 50% or more |

Adhesive performance

| Label base material | Substrate | Adhesion (N/15mm) |

|---|---|---|

| paper | glass | Breaking paper |

| CPP | Breaking paper | |

| PET | Breaking paper | |

| OPP | glass | 2.2 (Agglomeration) |

| CPP | 2.5 (agglomerate) | |

| PET | 2.9 (agglomerate) | |

| PET | glass | 4.9 (agglomerate) |

| CPP | 3.5 (agglomerate) | |

| PET | 4.1 (Agglomeration) |

* Sealing conditions: 100°C, 0.1 MPa, 0.3 sec.

Other common labels

Depending on the shape of the container, material, design, production process, etc., the following labels are also used.

| roll label | This is a type of label that is coated with hot melts at both ends of the label and wrapped around the container. It is possible to reduce CO2 emissions by making labels thinner and eliminating release paper. |

|---|---|

| shrink labels | After the tubular label is placed on the bottle, it is heated with steam to shrink the label and wrap it around the container. It can be used for irregular containers and has excellent design. |

| glue label | It is a label that is applied while applying glue dissolved in water to a paper label. Waste is low, and glue is relatively inexpensive. |

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Address Sales Department

TEL: +81-3-3272-3497