耐熱接着剤 ダイナレオ®VA9300シリーズ

製品概要

ダイナレオVA9300シリーズは、当社独自のポリマー設計により、耐熱性とATF耐性を両立させた熱硬化型(2液)接着剤です。その他、PPS基材への接着力の高さや柔軟性・剛性といった特長も兼ね備えております。

- 高耐熱のラミネート接着剤として、基材同士の貼り合わせが可能です。耐熱性が必要となる燃料電池や半導体周辺部材での使用に適しています。

- エージング前に冷蔵保管することでヒートシール接着層として使用できるため、オフラインでの封止や接着にも適しています。

| ラミネート接着剤 | ヒートシール接着剤 | |

|---|---|---|

| 使用例 |

燃料電池、蓄電池、

|

マイクロLED封止剤

|

特長

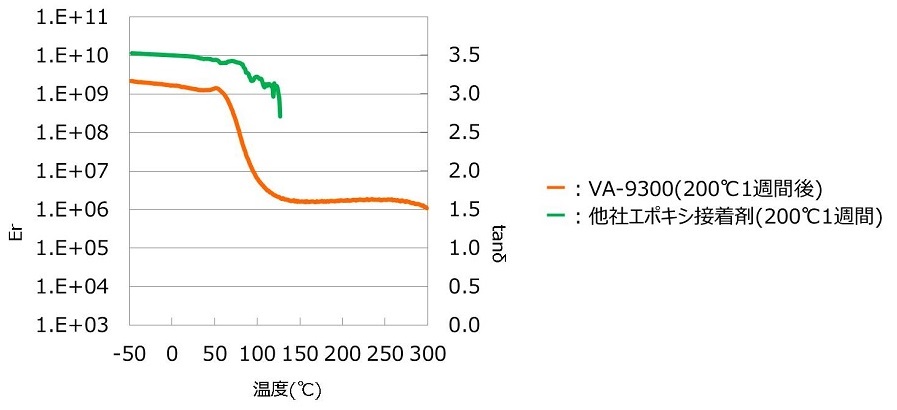

特長①高耐熱性(200℃)

高耐熱を実現しており、品質の安定性があります。他社エポキシ系接着剤が破断するのに対し、VA9300シリーズは200℃1週間後でも塗膜を維持します。

【200℃1週間経時後の動性粘弾性挙動】

特長②ATF含侵後の膨張率1%、特長③PPS基材への接着力の高さ

ATF(オートマチック・トランスミッション・フルード)に100℃8日間含浸しても変化率が少なく、製品Dでは膨張率は1%です。また、PPSやPEN、金属(SUS、銅、アルミ)の異種材料間の接着に適しています。

| 製品A | 製品B | 製品C | 製品D | ||

|---|---|---|---|---|---|

| ATF含浸後の 膨張率(%) |

破断強度(MPa) | 5% | 20% | 4% | 1% |

| 破断伸度(%) | 9% | 16% | 4% | 1% | |

| 対PPS 接着物性 T字剥離強度 (N/㎝) |

初期 | 材料破壊 | 材料破壊 | 材料破壊 | 材料破壊 |

| 100℃ 8日間後 |

材料破壊 | 材料破壊 | 材料破壊 | 材料破壊 | |

特長③柔軟性・剛性の向上を達成

独自の樹脂骨格により、トレードオフである伸びと強度を両立。困難とされる技術的上限曲線を越えた物性を実現しています。

エポキシ樹脂以上の剛性をもつ製品もラインナップしています。

【塗膜の破断強度・破断伸度】

| 製品A | 製品B | 製品C | 製品D | |

|---|---|---|---|---|

| 破断強度(Mpa) | 43.8 | 42.6 | 54.3 | 73.9 |

| 破断伸度(%) | 400 | 250 | 10 | 10 |

製品物性一覧

| 製品A | 製品B | 製品C | 製品D | ||

|---|---|---|---|---|---|

| 特長 | 強靭・柔軟化 | 剛性化 | |||

| 塗液外観 | 無色透明 | ||||

| 膜厚(㎛) | 20 | ||||

| 破断強度(MPa) | 43.8 | 42.6 | 54.3 | 73.9 | |

| 破断伸度(%) | 400 | 250 | 10 | 10 | |

| AFT含浸後の 膨張率(%) |

破断強度(MPa) | 5% | 20% | 4% | 1% |

| 破断伸度(%) | 9% | 16% | 4% | 1% | |

| 対PPS 接着物性 T字剥離強度 (N/㎝) |

初期 | 材料破壊 | 材料破壊 | 材料破壊 | 材料破壊 |

| 100℃ 8日間後 |

材料破壊 | 材料破壊 | 材料破壊 | 材料破壊 | |

※各種データは試験値であり、保証するものではありません。

ご要望に合わせてカスタマイズも可能です。

お問い合わせ

トーヨーケム株式会社 包装・工業材営業本部 営業1部

TEL:03-3272-0940