flexo printing solutions

Evolving flexo printing

Environmental measures, improvement of image quality, support for small lots, high variety, and short delivery times

Film flexo printing has been developed for only limited applications because of the wide variation in print quality.

However, due to technological innovations in plate making, printing machines, and peripheral materials, printing image quality has improved, making it possible to provide the market with features that are environmentally friendly and compatible with small lots.

Prepress

The formation of FTD (Flat Top Dot) enables high quality and stable image quality reproduction. Technological advances in plate materials and exposure machines contributed.

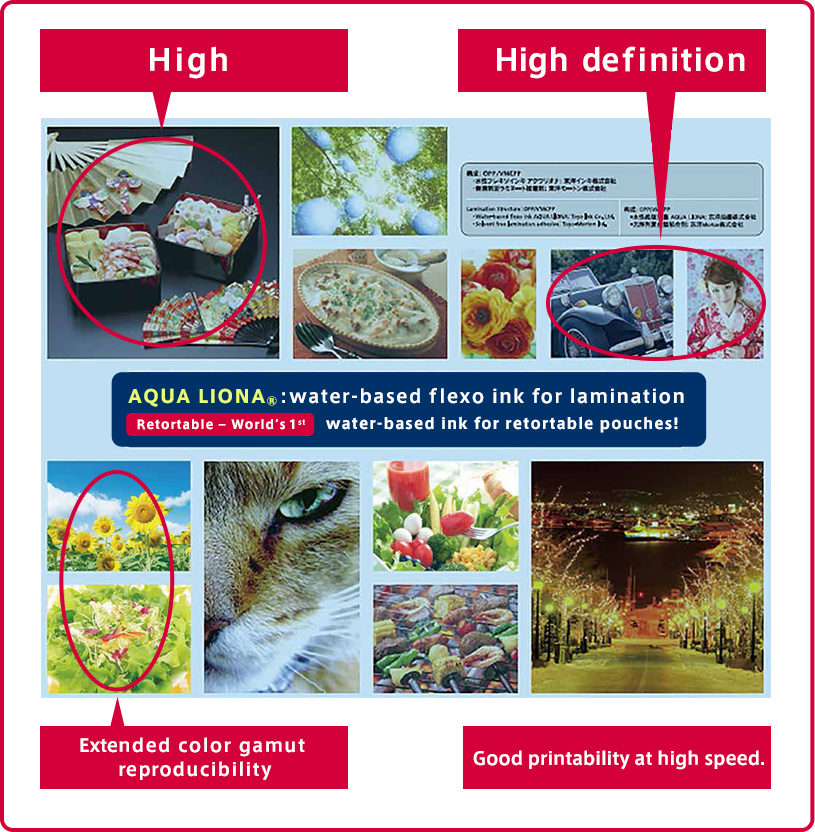

Inks

Oil-based flexo ink is the mainstream overseas, but inquiries about water-based flexo ink are increasing in Japan. Expanded lineup that can be used for various applications.

Printer

Various types of printing presses have been developed, including CI type, unit type, and stack type, and the development of functional printing machines that can handle small lots and a wide variety of products is progressing.

Materials & peripherals

Cushion tape and anilox affect density and reproducibility. Improvements in doctors, cleaning equipment, etc. contributed to increased productivity.

POINT

In order to produce high-quality flexible flexo packaging, it is essential to optimally combine the strengths of inks, plate making, printing machines, and materials.

TOYO INK 's strengths

artience group has Group Companies that have all the elements necessary to achieve high-quality flexo printing.

Plate making: TOYO FPP CO., LTD.

Introduced the latest plate making machine, XPCrystal. Researching combinations of plate-making conditions for high fine line/high color rendering.

Ink: TOYO INK CO., LTD.

Developed ink that has both printability and physical properties. Widely used for flexible packaging laminates, front printing packaging, etc.

adhesives: Toyo-Morton, Ltd.

Developing laminating adhesives that is ideal for water-based inks.

Material: TOYOCHEM CO., LTD.

Development of cushion tape aimed at improving work efficiency in terms of air release and removability.

Printing machine: Windmoller & Holscher

Introduced a W&H CI 8-color machine at the Saitama Factory.

Inquiries

TOYO INK CO., LTD. Marketing Headquarters

TEL:+81-3-3272-7693