Plasticizer-resistant water-based pressure sensitive adhesives for PVC substrates

It has also been confirmed that the amount of formaldehyde emitted is equivalent to F☆☆☆☆, so it can be used with confidence in interior materials for indoor applications.

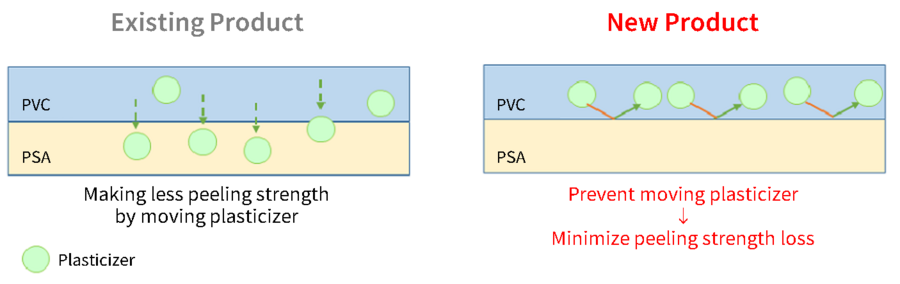

Technology to suppress decrease in adhesive strength by preventing plasticizer migration

Adverse effects of plasticizers on pressure sensitive adhesives

- PVC: polyvinyl chloride (PVC)

- Plasticizer: Additive to soften resin such as PVC

Plasticizer resistance technology

By using a special composition design that differs from conventional water-based pressure sensitive adhesives, we have succeeded in preventing the plasticizer contained in the PVC base material from migrating to pressure sensitive adhesives and suppressing the decline in adhesive strength.

Plasticizer-resistant water-based pressure sensitive adhesives

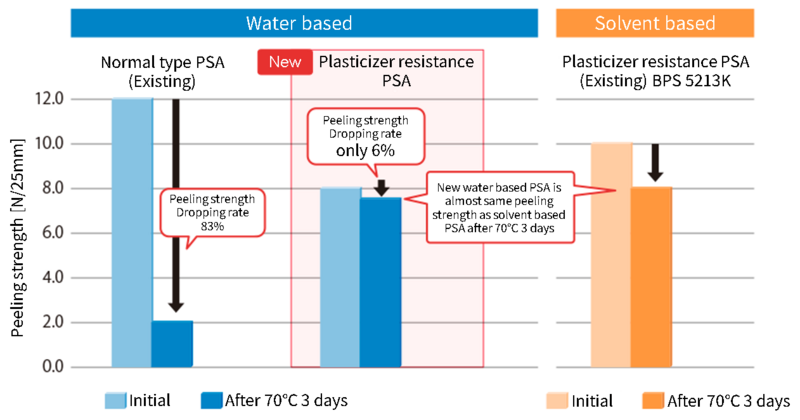

Adhesive strength comparison data over time

If a general-purpose water-based pressure sensitive adhesives is used for adhesive coating samples on PVC substrates, the adhesive strength will decrease significantly over time.

When using the new products BPW 6613 and BPW 6614, it is possible to suppress the decrease in adhesive strength to a greater extent than with solvent-based plasticizer-resistant pressure sensitive adhesives.

- Coating amount: 16±1g/m2, Base material: PVC film (contains 15% plasticizer), Curing: 1 week at room temperature, Adherent: Polished SUS, 24 hours after application

Product features

- Since it does not contain organic solvents, it is environmentally friendly, can be used in products for indoor applications, and also contributes to improving the working environment.

- External agency tests have confirmed that the amount of formaldehyde emitted is equivalent to F☆☆☆☆.

- Since it is a one-component type, there is no need for a curing agent compounding process.

| BPW6613 | BPW6614 | |

|---|---|---|

| Viscosity [mPa・s] Type B #4, 60rpm | >10,000 | 4,000 |

| Viscosity [mPa・s] Type B #4, 6rpm | 24,000 | ― |

| Type | High viscosity type For brush coating |

Viscosity adjustment type For coating with coater |

| how to use |

Can be dried at room temperature |

Can be processed into tape, etc. |

Application example

・Architectural exterior such as marking films

・Automotive parts such as wire harnesses

・Agricultural materials such as vinyl house repair tape

Please also refer here for the lineup of plasticizer-resistant pressure sensitive adhesives.

pressure sensitive adhesives lineup by function: PVC resistance (plasticizer resistance)

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-0940