Acrylic water-based pressure sensitive adhesives for low-temperature bonding Can be used sub-zero climate

Pressure sensitive adhesives in low temperature environments

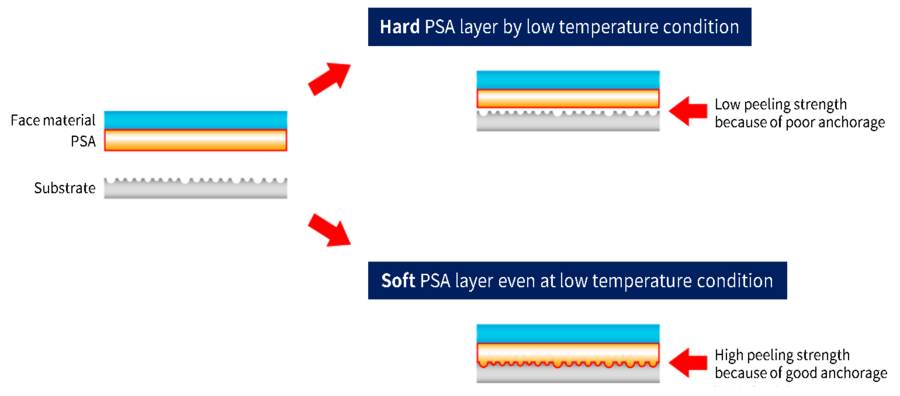

In general, even if pressure sensitive adhesives exhibits high adhesive properties at room temperature, when used in winter or in a low-temperature environment, its performance as an adhesive tends to deteriorate, such as poor adhesion to pressure sensitive adhesives there is.

The new product we are introducing today is an acrylic water-based based pressure sensitive adhesives with excellent adhesive properties in low-temperature environments.

It exhibits good adhesion even when applied in cold environments or in low-temperature environments such as inside a refrigerator.

Acrylic water-based based pressure sensitive adhesives for low temperature adhesive BPW 6681

Characteristics

- It exhibits good adhesive strength even when pasted in negative environments.

- It has high adhesion and adhesion to various adherends and base materials that are difficult to anchor, such as foam.

- It is an environmentally friendly product as it is a water-based pressure sensitive adhesives that does not contain solvents.

- Since it is a one-component curing type, there is no need for a compounding process.

- Production is possible not only in Japan but also at our base in China.

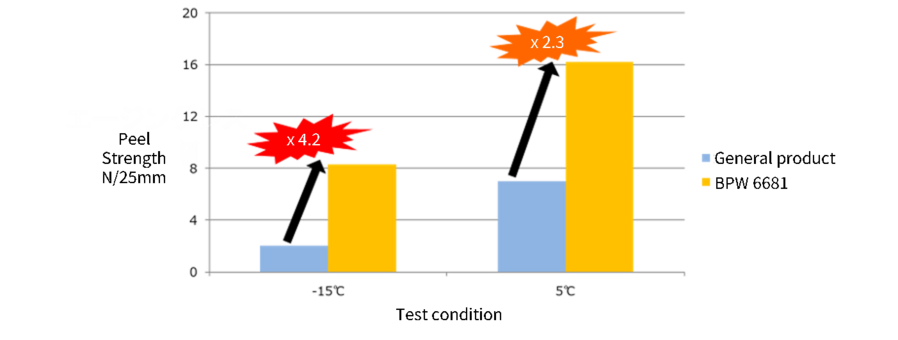

Adhesive properties of urethane foam base material

| Test condition | Substrate | Dwell time | General products | BPW6681 | |

|---|---|---|---|---|---|

| Peeling strength [N/25mm] |

-15℃ | To SS | Immediately | 2.0 | 8.3 |

| 5℃ | Immediately | 7.0 AT | 16.2 | ||

| 23℃ | Immediately | 11.0 AT | 20.6 | ||

| 24hrs | 10.5 AT | 25.7 | |||

| PE | Immediately | 7.0 AT | 12.6 | ||

| 24hrs | 6.5 AT | 14.8 | |||

| Ball tack (#) | 18 | 20 | |||

- AT: all transfer

- Coating weight: 60g/m2, Face material: Urethane foam

- Adhesion measurement conditions: Sample and adherend are left in the measurement atmosphere for 30 minutes or more and then bonded together.

(Initial) Measured immediately after crimping (Permanent) Measured after 24 hours

Adhesive properties on paper base material

| Test condition | Substrate | Dwell time | General products | BPW6681 | |

|---|---|---|---|---|---|

| Peeling strength [N/25mm] |

-15℃ | To SS | Immediately | 2.0 | 11.5 |

| 5℃ | Immediately | 8.9 | 15.7 | ||

| 23℃ | Immediately | 20.5 | 24.3 | ||

| 24hrs | 22.5 | 25.1 | |||

| PE | Immediately | 12.0 | 19.2 | ||

| 24hrs | 15.0 | 22.2 | |||

| Ball tack (#) | 11 | 11 | |||

- Coating weight: 25g/m2, Face material: High quality paper

- Adhesion measurement conditions: Sample and adherend are left in the measurement atmosphere for 30 minutes or more and then bonded together.

(Initial) Measured immediately after crimping (Permanent) Measured after 24 hours

Expected usage examples

・Packing tape

We provide detailed materials and test samples for BPW 6681.

In addition to this product, we also have a lineup that is suitable for low temperatures, so please feel free to contact us.

Click here for solvent-based low-temperature pressure sensitive adhesives.

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-0940