What is the difference between adhesives, pressure sensitive adhesives, and hot melts

Here, we would like to introduce only `` adhesives,'' `` pressure sensitive adhesives,'' and hot melts.''

- Difference between "adhesives", "pressure sensitive adhesives" and "hot melts"

- Examples of use of adhesives, pressure sensitive adhesives, and hot melts (composition, coating)

- Field of use

- Our products

Difference between "adhesives", "pressure sensitive adhesives" and "hot melts"

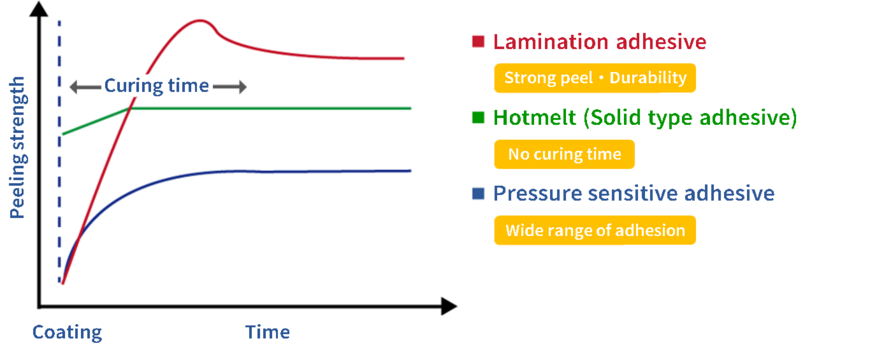

"Adhesives," "adhesives," and "hot melts" have the function of "pressure sensitive adhesives," but the general differences can be expressed as shown in the diagram below.

Due to these differences in performance, each product is used for the following purposes.

adhesives (laminating adhesives)

Various packaging materials for food applications, highly durable parts for energy and electronics, etc.

Pressure sensitive adhesives

Sticker labels, healthcare products, electronics-related products such as protective films and liquid crystal lamination, etc.

Hot-melt

PET bottle body labels, yogurt cap seals (heat sealant for lids), internal fixation of sanitary products (diapers, napkins), slip prevention, etc.

Examples of use of adhesives, pressure sensitive adhesives, and hot melts (composition, coating)

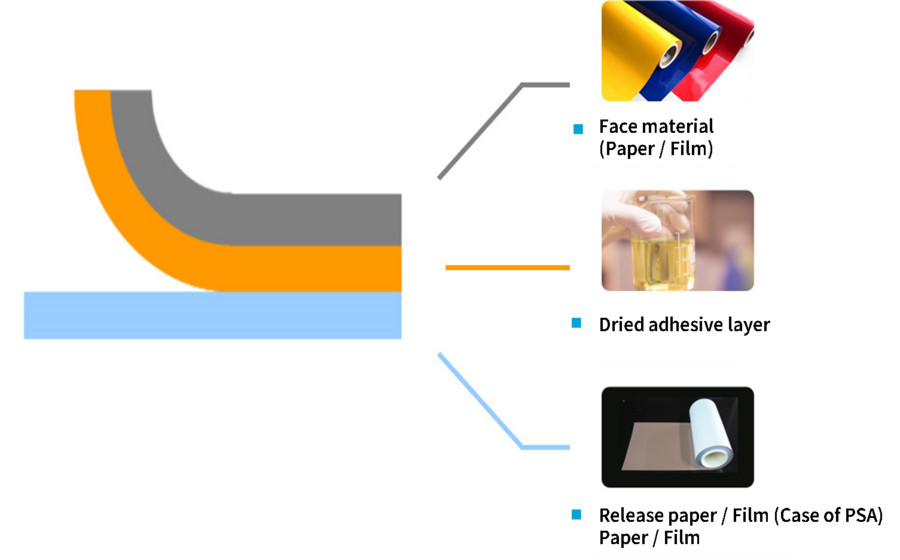

Most adhesives, pressure sensitive adhesives, and hot melts are not applied directly with a brush, but are processed into the compositions shown below.

* Note:

hot melts is usually provided in solid form, and it is necessary to melt the resin by applying heat and process it into a liquid. (The photo is an example of hot melts)

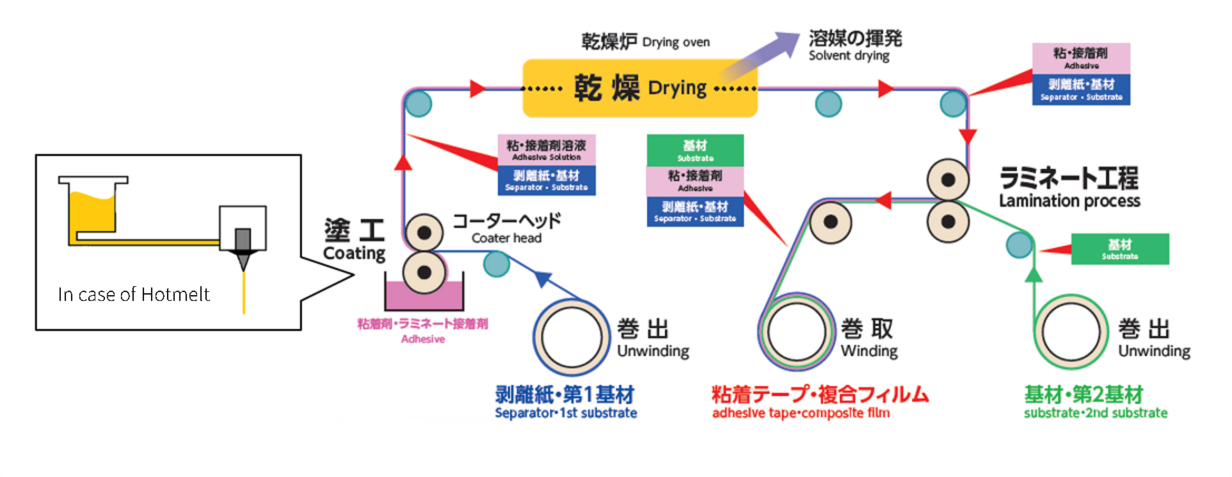

In order to make a product with this kind of composition, knowing what kind of equipment to use for coating is also an important element that requires know-how. I will write down the model diagram.

- hot melts have supply equipment that melts the resin before coating. Drying process is basically not necessary.

Of particular importance in a coating machine are the type of coater head and drying oven. The design and settings will vary depending on the viscosity of the liquid to be applied, the speed of the machine, and the base material (paper or film type).

There are also coating methods such as spray coating and applying it directly to the object you want to attach, such as using a glue gun, and there are also products that do not require a coating machine.

In this way, it is necessary to select a product that is compatible with the coating machine and coating method, taking into account the characteristics of the liquid.

Field of use

| Energy | Electronics | medical care | Automotive | Food and beverage | life industry | |

|---|---|---|---|---|---|---|

| Adhesives | ● | ● | ● | ● | ● | ● |

| Pressure sensitive adhesives | ● | ● | ● | ● | ● | |

| Hot melts | under development | ● | ● | ● |

If you are looking for something that requires "sticking" performance, please contact us.

Our products

Inquiries

TOYOCHEM CO., LTD. Packaging and Industrial Materials Sales Division Sales Department 1

TEL:+81-3-3272-0940