Technology 01

100km into the future,

with dispersion technology

artience has developed the dispersion technology that it has refined over many years in various fields.

We offer new solutions.

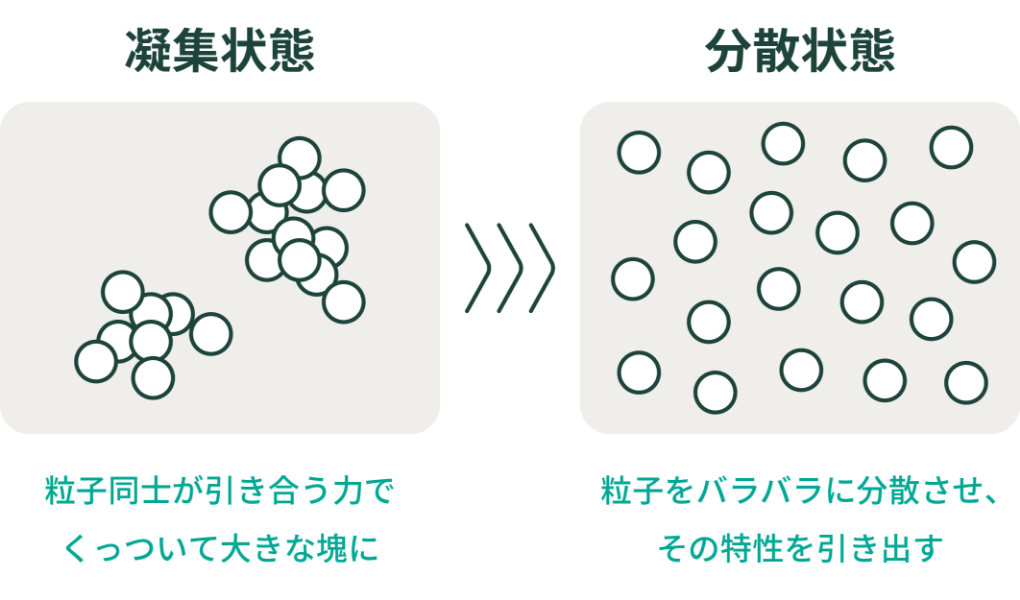

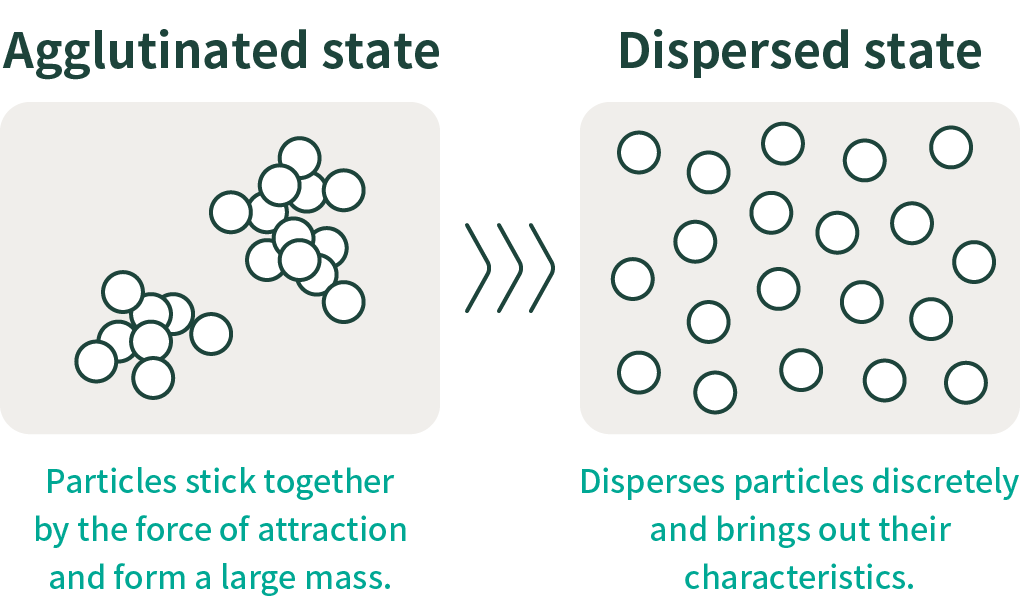

Dispersion technology is a technology that loosens solidified particles and distributes them separately in liquids and solids. By controlling the dispersion, the potential of the particles is maximized, and the desired performance can be achieved.

CASE 01 Lithium-ion battery Technology supporting the evolution of lithium-ion batteries

Lithium-ion batteries used in electric vehicles (EV) and other vehicles. Our advanced dispersion technology also helps to improve its performance.

What is "CNT" expected to improve battery performance?

Lithium-ion batteries are discharged and charged by the movement of lithium ions and electrons. Materials that help electrons move are conductive additives. In the past, carbon black was the most common material for conductive additives, but carbon nanotubes (CNT), a new material with superior conductive performance, have come to attract attention.

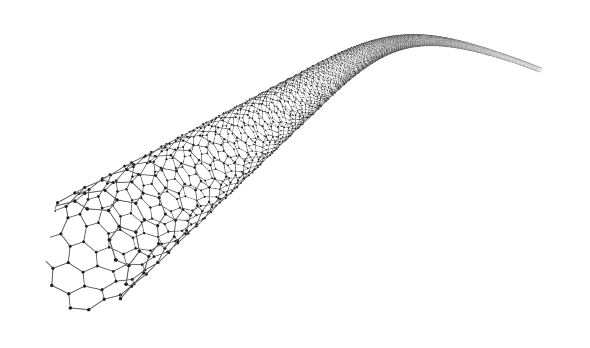

A carbon substance about 1/50,000th the thickness of a human hair. It is as strong as diamond and has excellent electrical and thermal conductivity.

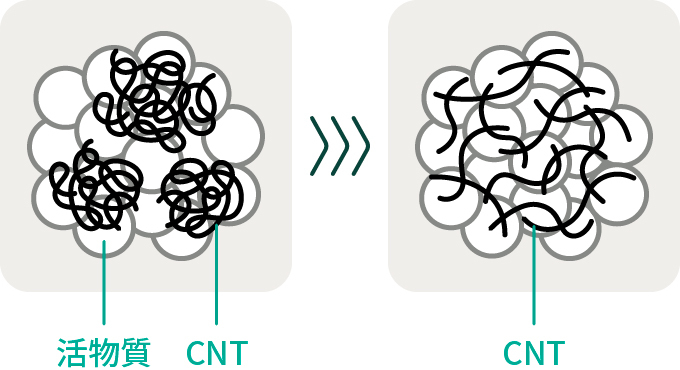

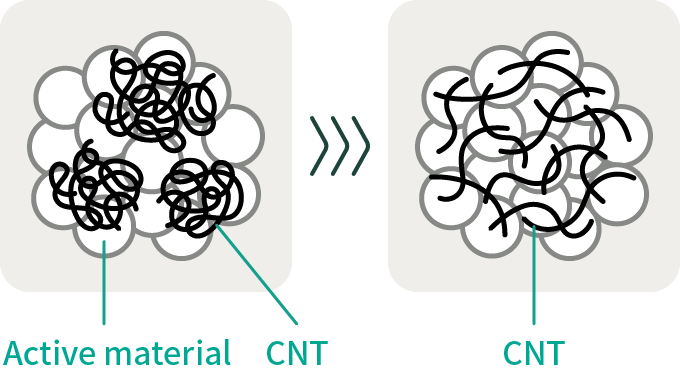

Successful Ideal Dispersion of CNT

CNT have very high performance, but unlike carbon black, they are fibrous, so they are easily entangled with each other and difficult to disperse, making it difficult to take advantage of their excellent characteristics. However, with our unique dispersion technology, we have succeeded in carefully loosening the entangled CNT while maintaining an appropriate length, and maintaining the ideal dispersion state.

CNT dispersions Enables Higher Battery Capacity

Optimal dispersion of CNT has led to the development of dispersions that maximizes the effect with a minimum of CNT. It is now possible to increase the amount of active material, and the capacity of lithium-ion batteries has been increased. The cruising range of EV has increased, which has also led to improved fast-charging performance.

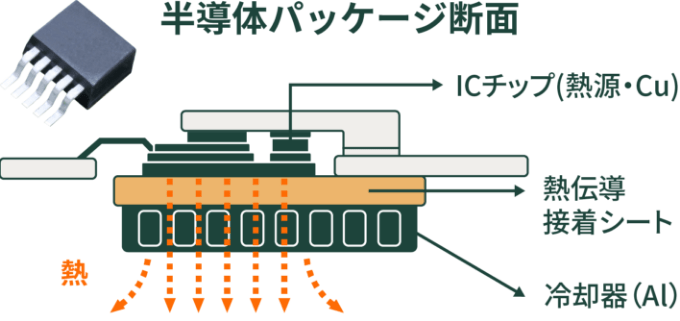

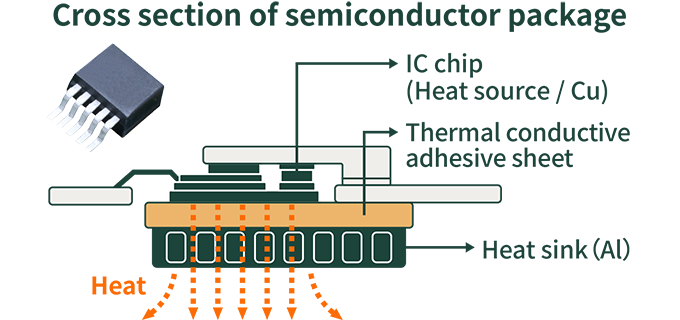

CASE 02 Power semiconductors The evolution of electronic devices with dispersion technology that efficiently dissipates power semiconductor heat

As electronic devices become smaller and more sophisticated, there is a growing need to suppress damage and functional deterioration caused by heat generation in IC chips. Therefore, we have developed a heat dissipation sheet that efficiently dissipates the heat generated by the IC chip to the cooler.

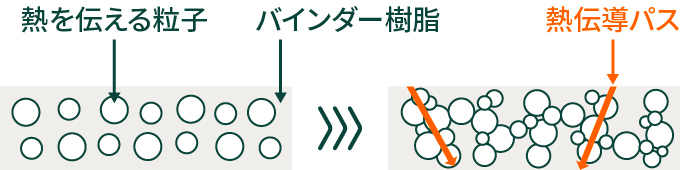

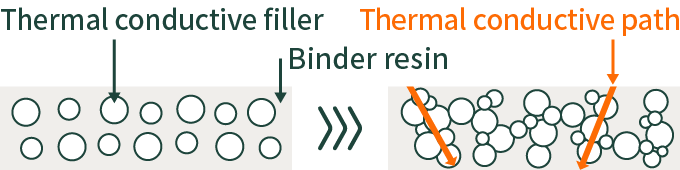

In order to dissipate heat, it is necessary to create a path for heat. We have achieved this efficiently by deliberately distributing particles that transmit heat unevenly. It combines superior dispersion technology with polymer design technology to increase the filling rate of particles that transfer heat to increase thermal conduction efficiency, while also improving the flexibility and adhesion of the sheet.

CASE 03 Lens/Display Dispersion technology for light control makes viewing easier and more beautiful

Smartphones and tablets, camera lenses, etc. Optical control technology is indispensable for the development of next-generation electronic and optical devices that are easier to see and more beautiful. We contribute to solving a wide range of issues by uniformly dispersing particles that suit each purpose, such as shading, reflection, and diffusion, and providing them as paste-like materials.

CASE 04 Electronics Products Dispersion × coating for electronic products enhances film functionality

Plastic films are also widely used in the field of electronics. By dispersing particles with various properties such as antistatic and refractive index control in coating agents and improving the functionality of plastic films, we support the diversification and performance of electronic products.