artience Strengths | Integrated Report 2024Proactive Investing to Open the Way toward Market Strategies for New Businesses

Published on June 28, 2024

This page has been translated using AI.

They are significant products that help ubiquitize electric vehicles (EVs), which is a growing market. We see CNT dispersions as a strategic priority business that will drive the Group’s growth, and we are increasing our efforts in this area.

Koji Obata

Evolving from printing ink pigments to CNT dispersions

The technologies supporting the manufacturing of the CNT dispersions that are applied in automotive LiBs are originally based on pigment dispersion technologies for printing inks.

A black pigment called carbon black is used to print newspapers. Its conductivity is so high that it has also been used in antistatic coatings for audio cassette tapes, VHS video tapes and other recording materials. Developed from these technologies, carbon black dispersions were used as conductivity agents in LiBs for hybrid vehicles for the first time in 2015.

However, it is difficult to disperse carbon black, so this made it difficult to advertise our uniqueness. At that time, I learned through marketing activities that in China, people had begun using CNT as an conductivity agent in LiBs. We thus started working to develop CNT dispersions. CNT is a material that helps improve LiB performance since a smaller amount of CNT will fulfill the role of a larger amount of carbon black. However, its dispersion was very difficult and there were big hurdles to clear before it could be commercialized. The advanced dispersion technologies that we had cultivated since our foundation greatly aided our commercialization of CNT.

After they were first used in 2019, our conductive CNT dispersions for LiB cathode materials have been used by a series of large LiB manufacturers. In February 2024, Primeearth EV Energy Co., Ltd. began using our CNT dispersions for Toyota’s hybrid vehicles. It is the first time that CNT dispersions are being used as conductivity agents in the materials used to make LiB cathodes for a mass-produced vehicle made in Japan.

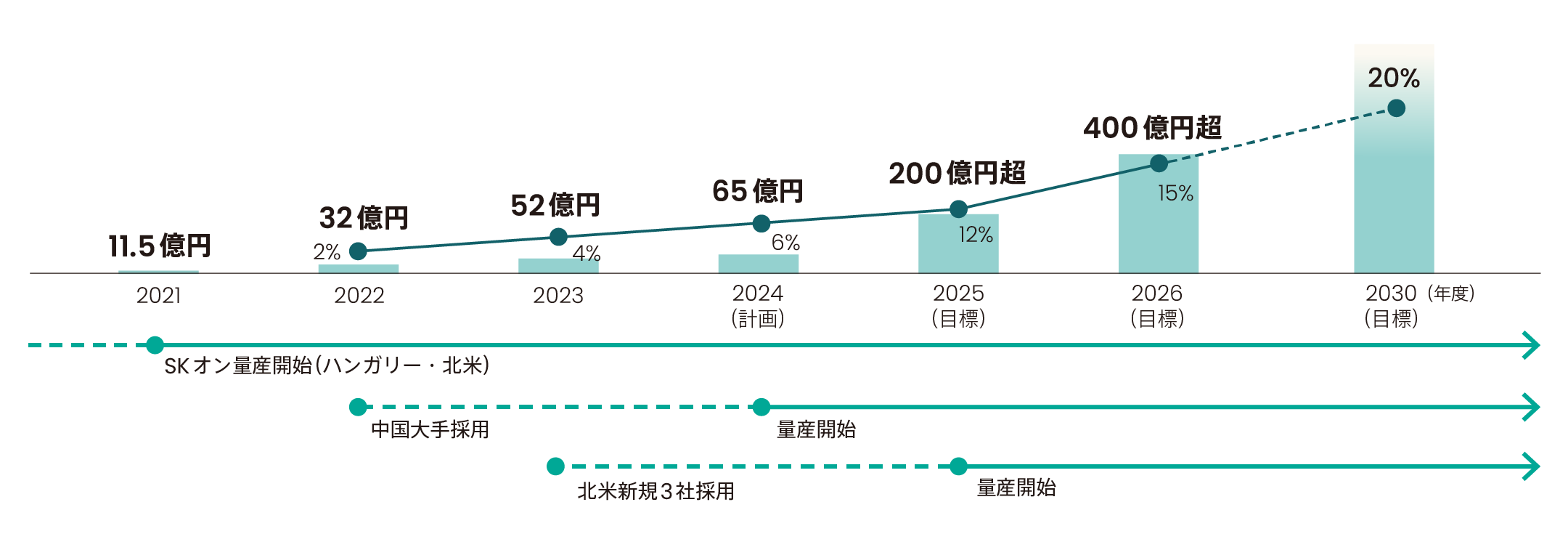

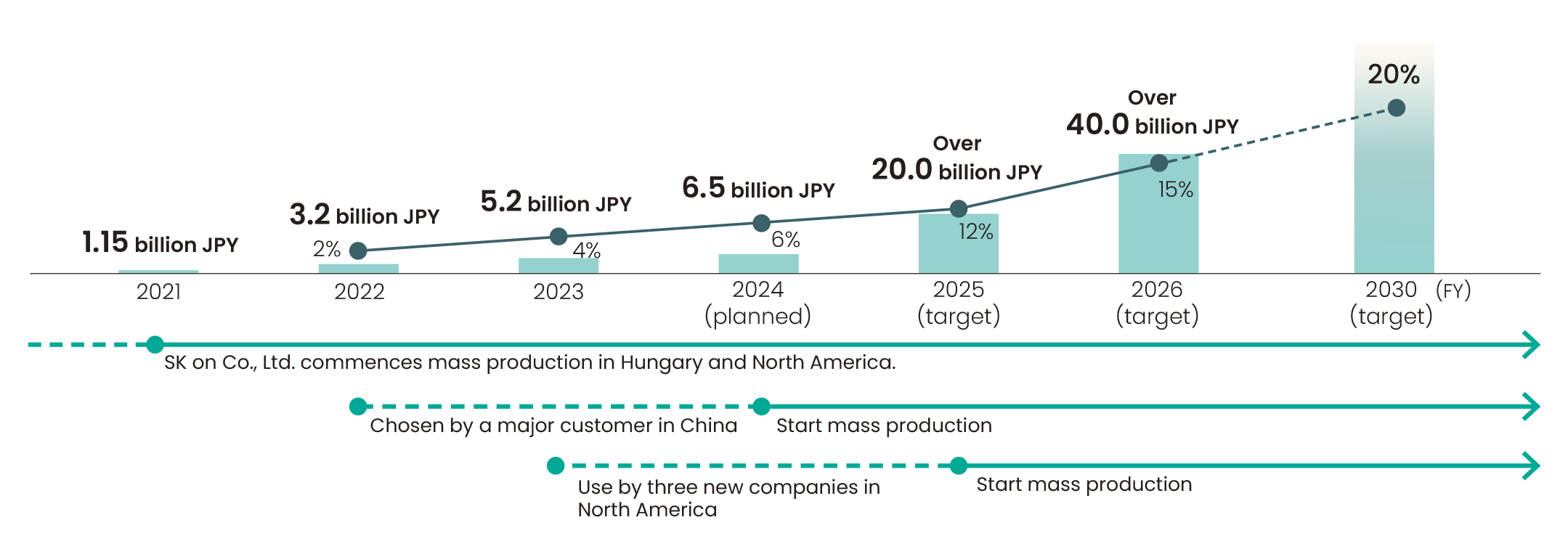

- Share of total demand for automotive LiB capacity (GWh)

Our strengths are technologies, dispersants, and optimization of production processes

We not only have CNT dispersion technologies, but also develop dispersants independently, and establish a high-level of production process. We have strengths in three areas; the dispersion technologies, the development and improvement of dispersants, and the optimization of production processes.

The most important thin in LiB safety is the prevention of contamination with any metallic foreign matter. The contamination of CNT dispersions with metallic foreign matter would cause a short circuit between the cathode and the anode of the battery, increasing the risk of ignition and heat generation. The level of contamination prevention requested varies from customer to customer. We closely discuss the issues and coordinate with customers to develop a system for meeting their quality requirements.

We are convinced that the trust customers have in us and the expansion of sales that we are achieving today are a result of our customization of products to meet their needs and the establishment of robust quality management and assurance systems in addition to the CNT dispersion technologies.

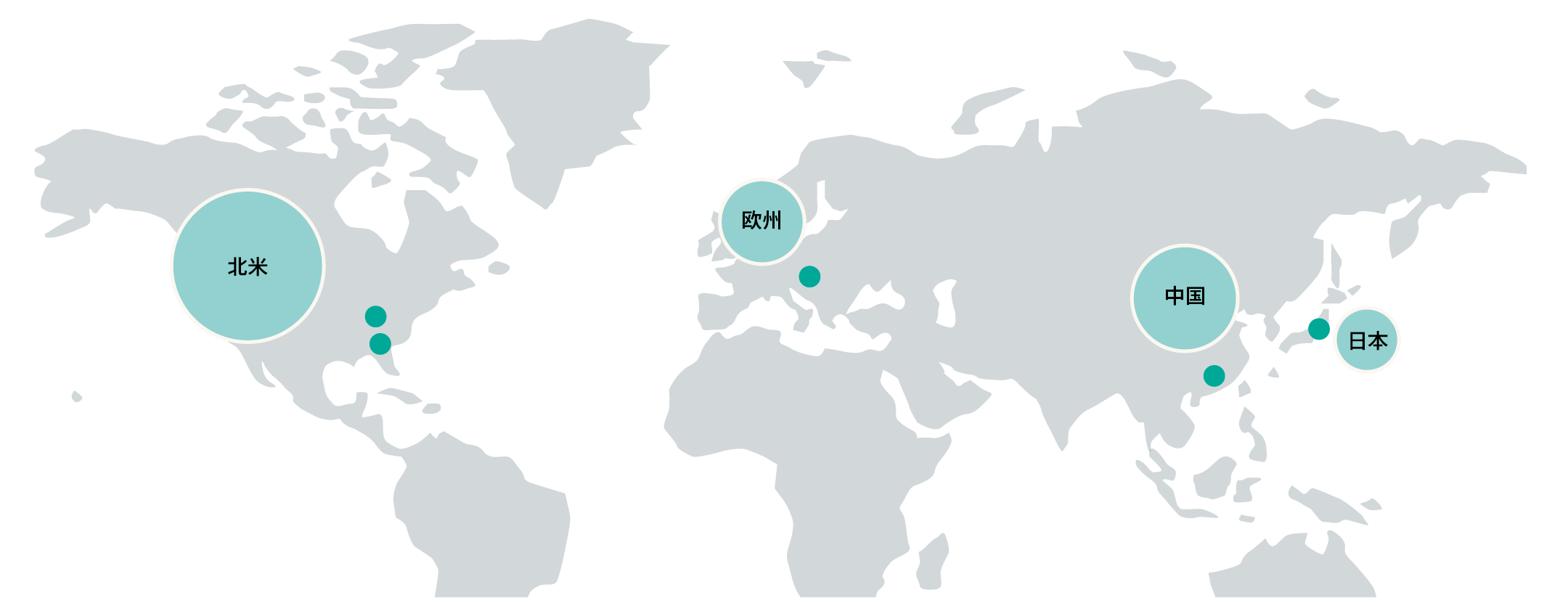

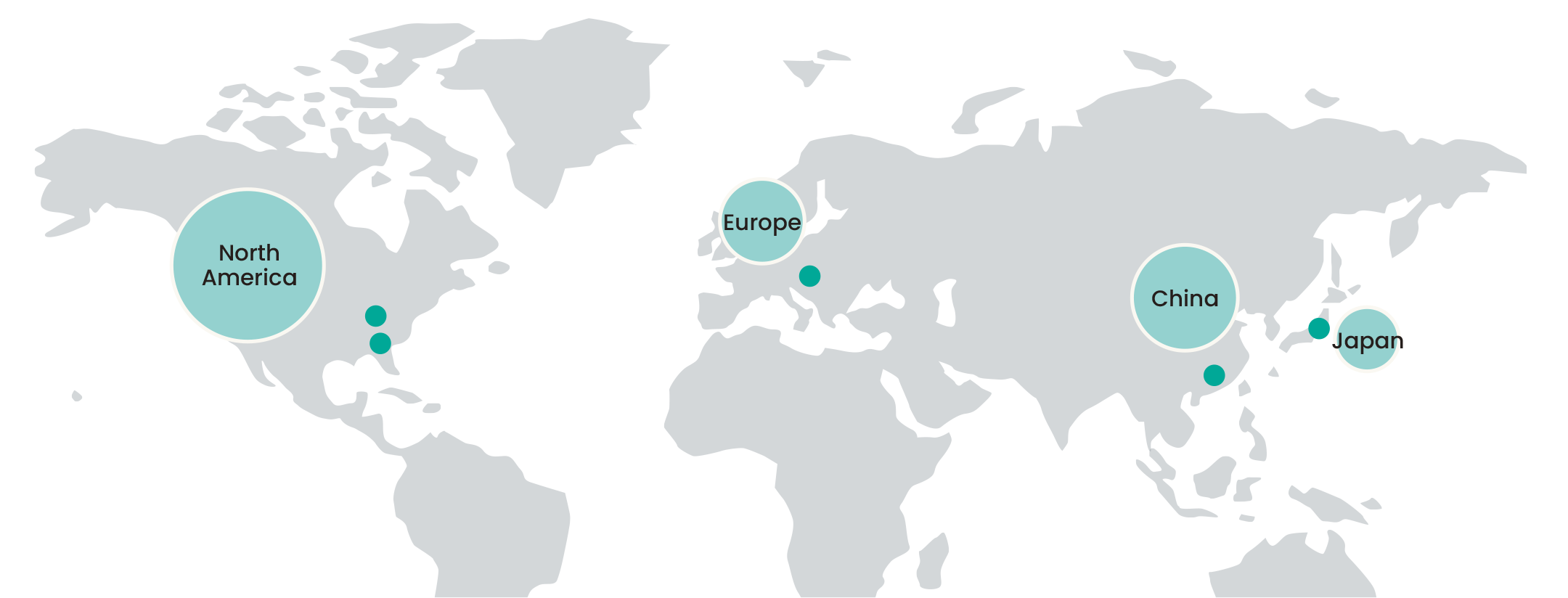

The trend towards EVs will not change, even through there are political risks

Currently, we produce CNT dispersions for LiBs in the United States, Hungary, China and Japan. In FY2023, we established a second production base in the United States. LioChem is a subsidiary based in the US state of Georgia and our first LiB production base in the United States. It has been mainly producing colorants for plastics and gravure inks since the 1980s. Today, John Easley is the President of the company. In the process of establishing the new base, he secured a workforce, negotiated local subsidies and took other steps to support our business independently.

In some countries, there may be some political risks, such as the drastic changes in attitudes towards the reduction of CO2 emissions due to government policies and other factors. But on a global scale, CO2 emissions reduction policies are common, and the trend towards EVs will not change. It may possibly stagnate temporarily, but I assume that the upward trend will continue.

Increasing investments aiming to have a 20% share of the global market in FY2030

We have set the target of having a 20% share of the global market for CNT dispersions for LiBs (to total demand for automotive LiBs capacity) in FY2030. Given that the time it takes to develop a vehicle in the automobile industry, we are currently working on the business with an eye towards the future beyond the artience 2027 medium-term management plan.

With the global trend toward decarbonization, the shift to EVs is progressing rapidly. It is forecast that by 2030 the global LiB market will grow to five to ten times its size in 2020 and it will continue to expand. The pace of the growth of the EV market decreased in the second half of 2023, but we are certain that it is temporary and that the upward trend will continue in the future.

I believe that the goal of having a 20% share of the global market in FY2030 is reasonably achievable.

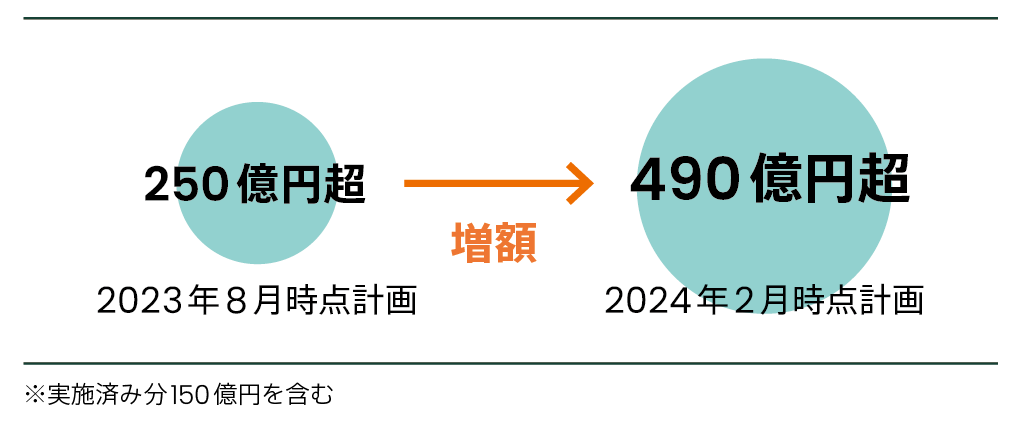

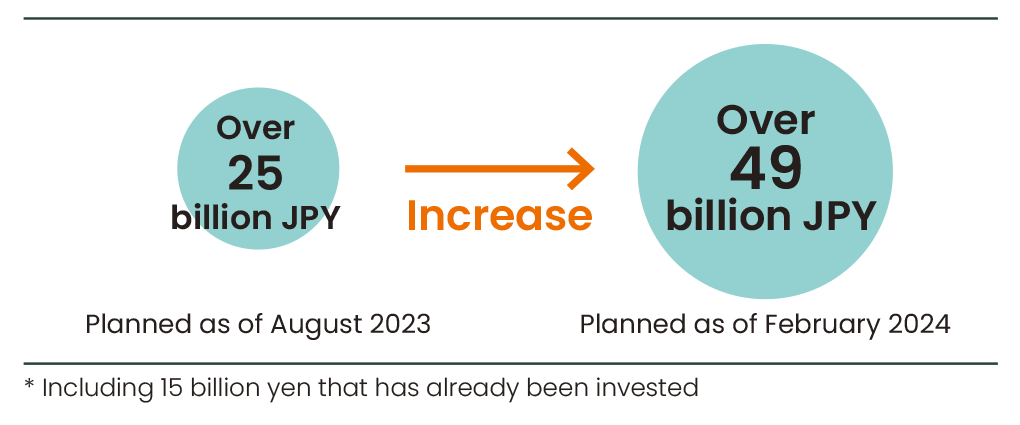

To support the achievement of this goal, we have increased the cumulative total investment planned from over 25 billion yen to over 49 billion yen. The Group has never invested this much in a single project before. In this process, we procured 15 billion yen from the Development Bank of Japan (DBJ) to be used in capital investments. We assume that the DBJ closely examined our strategy and made the decision to give us the loan.

Cumulative Investment Plans for this Business (2019~)

Creating value that resonates with the senses through CNT dispersions

We are engaged in B2B businesses and general consumers never pick up our products directly from the shelves. However, we will collaborate closely with our direct customers such as battery manufacturers and carmakers to surprise and excite general consumers by increasing EVs’ driving range and by improving their quick charging capabilities leveraging the CNT dispersions that we supply.

We will propose many different types of value to markets in collaboration with our direct customers. We expect that this will increase our market value. In our business activities, we will pay attention to providing value that appeals to the senses of the consumers who use the final products.

Materials for lithium-ion batteries

Project briefing materials (held on August 20, 2024)

CNTs for lithium-ion batteries dispersions Business Briefing Presentationdata of Carbon Nanotube Dispersions Business for Lithium ion Battery Business Briefing( PDF:2,081KB)